Resin SZUV-T1120-high temperature resistance

General Introduction

Characteristics:

SZUV -T1120 is a yellow SL resin which has unmatched thermal performance. It can withstand temperatures in excess of 200℃ at a short time and 120℃ at a long time. It is designed for handling a wide variety of high temperature and adverse testing applications.

Typical features

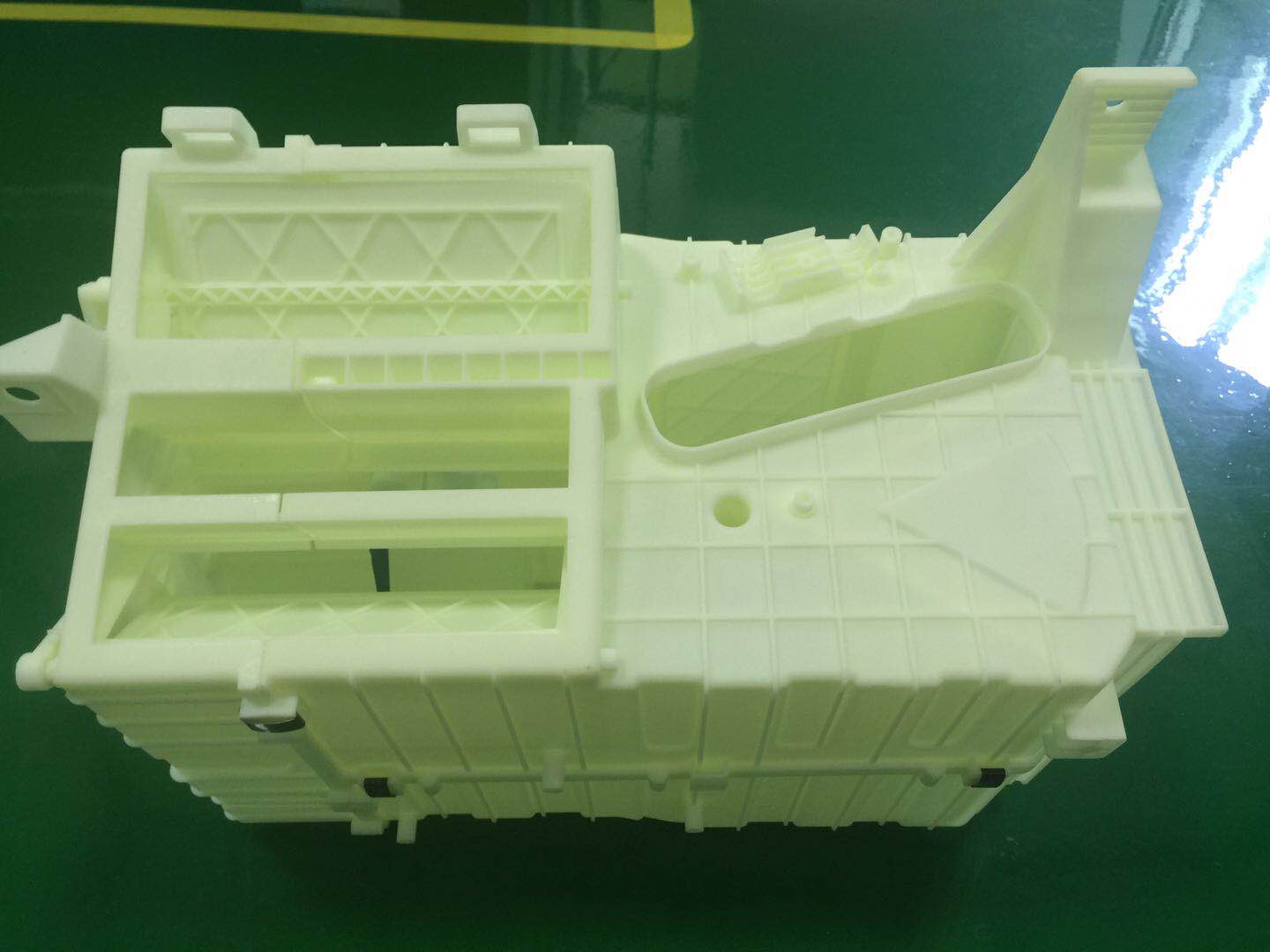

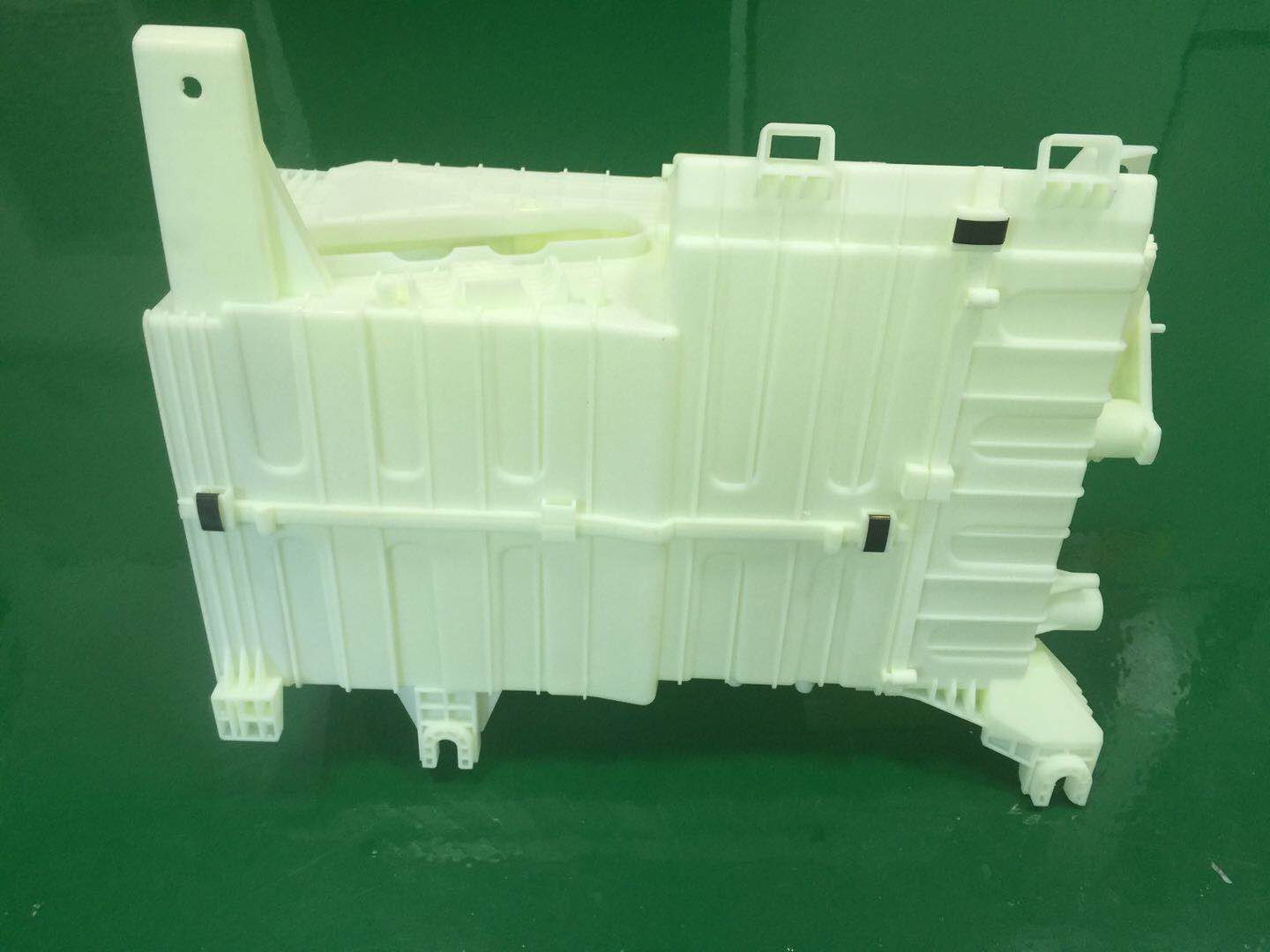

HIGH STRENGTH and GOOD RESISTANCE

SZUV-T1120 can stand up humidity, water and solvents, such as gasoline, transmission fluid, oil and coolant. With its unmatched heat resistance, it is suitable for flow, HVAC, lighting, tooling, molding and wind tunnel testing applications.

-BUILD FASTER and DEVELOP FASTER

By providing fast output and parts with a smooth, easy-to-handling surface, SZUV-T1120 can finishing your project from drawing to testing parts in the shortest time.

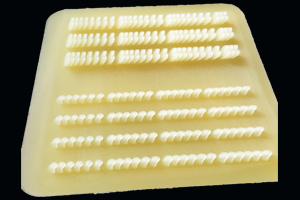

Application Cases

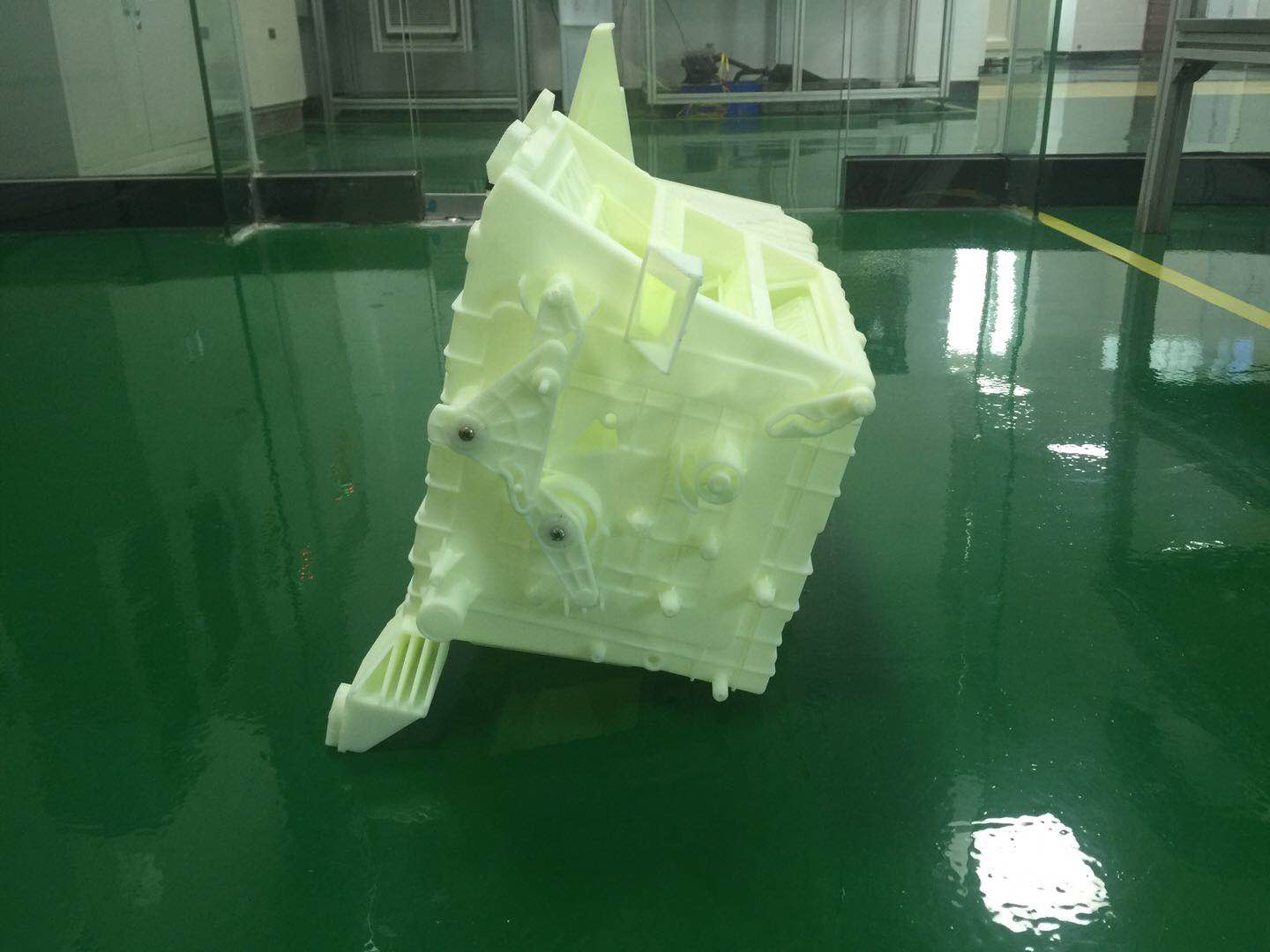

-Under-the hood component testing

-High temperature RTV molding

-Wind tunnel testing

-Lighting fixture testing

-Composite autoclave tooling

-HVAC component testing

-Intake manifold testing

-Orthodontics

APPLICATION FIELDS

Education

Hand Molds

Auto Parts

Packaging Design

Art Design

Medical

PHYSICAL PROPERTIES (LIQUID)

| Appearance | white |

| Density |

1.13g/cm3 @ 25 ℃ |

| Viscosity |

400~480 cps @ 29 ℃ |

|

Dp |

0.152mm |

| Ec |

7.6 mJ/cm2 |

| Building layer thickness |

0.05 ~ 0.12mm |

MECHANICAL PROPERTIES (POST-CURED)

| Measurement |

Test Method |

Value | |

|

90-minute UV post-cure |

90-minute UV +2 hours@160℃ thermal post-cure |

||

| Hardness, Shore D | ASTM D 2240 | 87 | 91 |

| Flexural modulus, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Flexural strength, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Tensile modulus, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Tensile strength, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation at break | ASTM D 638 | 4-8% | 4-6% |

| Impact strength, notched lzod, J/m | ASTM D 256 | 18-30 | 16-23 |

| Heat deflection temperature, ℃ | ASTM D 648 @66PSI | 81 | 98 |

| Glass transition, Tg, ℃ | DMA,E’peak | 100 | 111 |

| Coefficient of thermal expansion, E6/℃ | TMA(T<Tg) | 79 | 86 |

| Thermal conductivity, W/m.℃ | 0.171 | ||

| Density | 1.24 | ||

| Water absorption | ASTM D 570-98 | 0.49% | 0.46% |

Mechanical Properties of Post-Cured Material

|

MEASUREMENT |

TEST METHOD

|

|

VALUE |

|

|

|

90-minute UV post-cure |

90-minute UV +2 hours@160℃ thermal post-cure |

|

Hardness, Shore D |

ASTM D 2240 |

87 |

91 |

|

Flexural modulus, Mpa |

ASTM D 790 |

2678-3186 |

3502-3631 |

|

Flexural strength, Mpa |

ASTM D 790 |

60-80 |

90-101 |

|

Tensile modulus, MPa |

ASTM D 638 |

2840-3113 |

3484-3771 |

|

Tensile strength, MPa |

ASTM D 638 |

58-67 |

50-62 |

|

Elongation at break |

ASTM D 638 |

4-8% |

4 -6% |

|

Impact strength, notched lzod, J/m

|

ASTM D 256

|

18~30

|

16~23 |

|

Heat deflection temperature, ℃

|

ASTM D 648 @66PSI

|

81 |

98

|

|

Glass transition,Tg ,℃ |

DMA,E”peak

|

100 |

111

|

|

Coefficient of thermal expansion, E6/℃ |

TMA(T<Tg)

|

79

|

86

|

|

Thermal conductivity, W/m.℃ |

|

0.171 |

|

|

Density |

|

1.24 |

|

|

Water absorption |

ASTM D 570-98 |

0.49% |

0.46% |