Resin SZUV-T1120-héich Temperatur Resistenz

Allgemeng Aféierung

Charakteristiken:

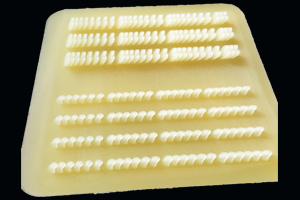

SZUV -T1120 ass e giel SL Harz deen oniwwertraff thermesch Leeschtung huet. Et kann Temperaturen iwwer 200 ℃ a kuerzer Zäit an 120 ℃ laang halen. Et ass entwéckelt fir eng breet Varietéit vun héich Temperaturen an negativ Testapplikatiounen ze handhaben.

Typesch Fonctiounen

HIGH STÄRK a GUTT Widderstand

SZUV-T1120 kann Fiichtegkeet, Waasser a Léisungsmëttelen ophalen, wéi Benzin, Transmissiounsflëssegkeet, Ueleg a Killmëttel. Mat senger oniwwertraff Hëtztbeständegkeet ass et gëeegent fir Flow, HVAC, Beliichtung, Tooling, Formen a Wandtunnel Testapplikatiounen.

-BUILD SCHNEIDER a SCHNEIDER entwéckelen

Andeems Dir séier Output an Deeler mat enger glatter, einfach ze handhaben Uewerfläch ubitt, kann SZUV-T1120 Äre Projet vun Zeechnen bis Testen Deeler an der kuerzer Zäit fäerdeg maachen.

Applikatioun Fäll

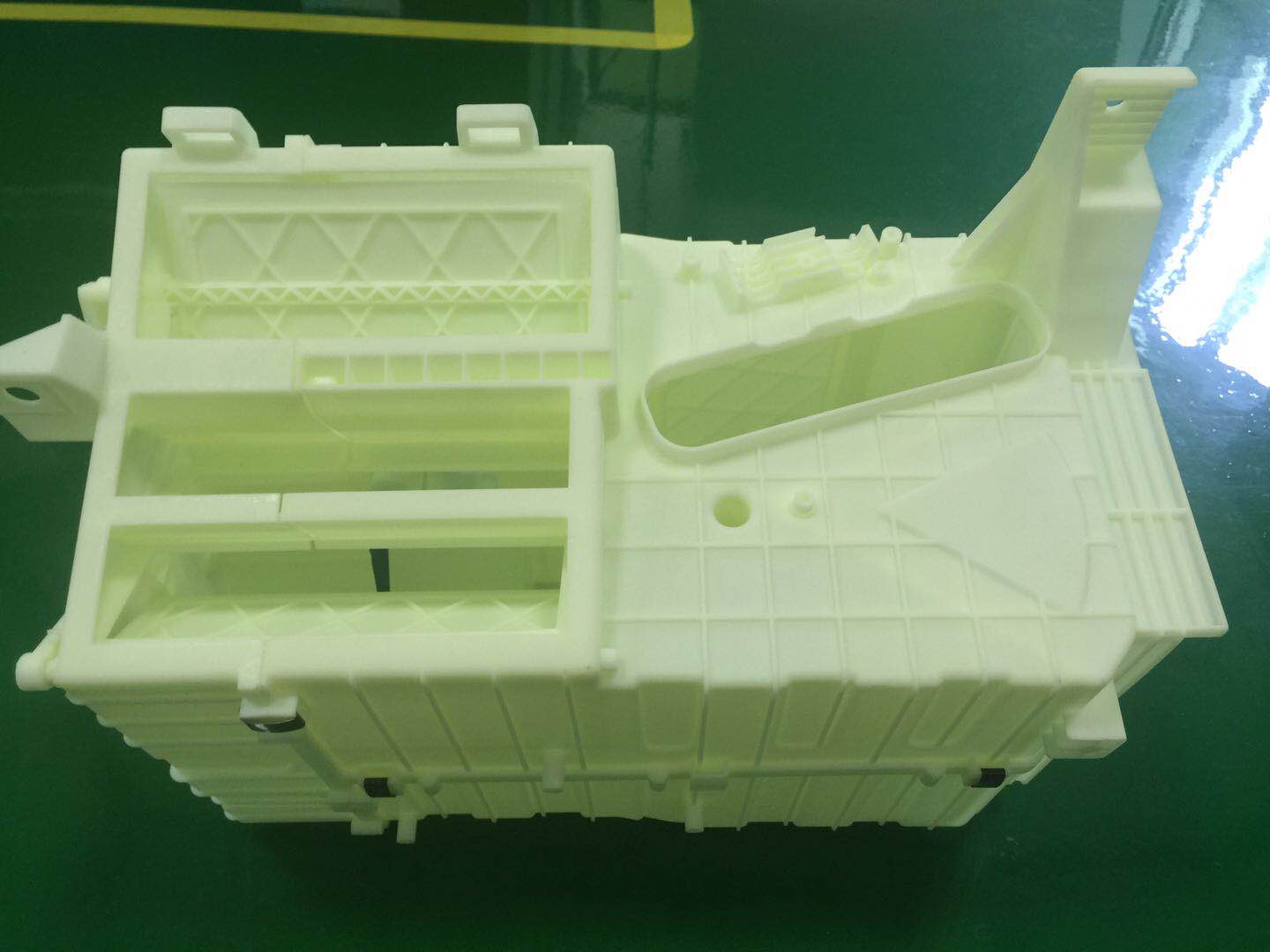

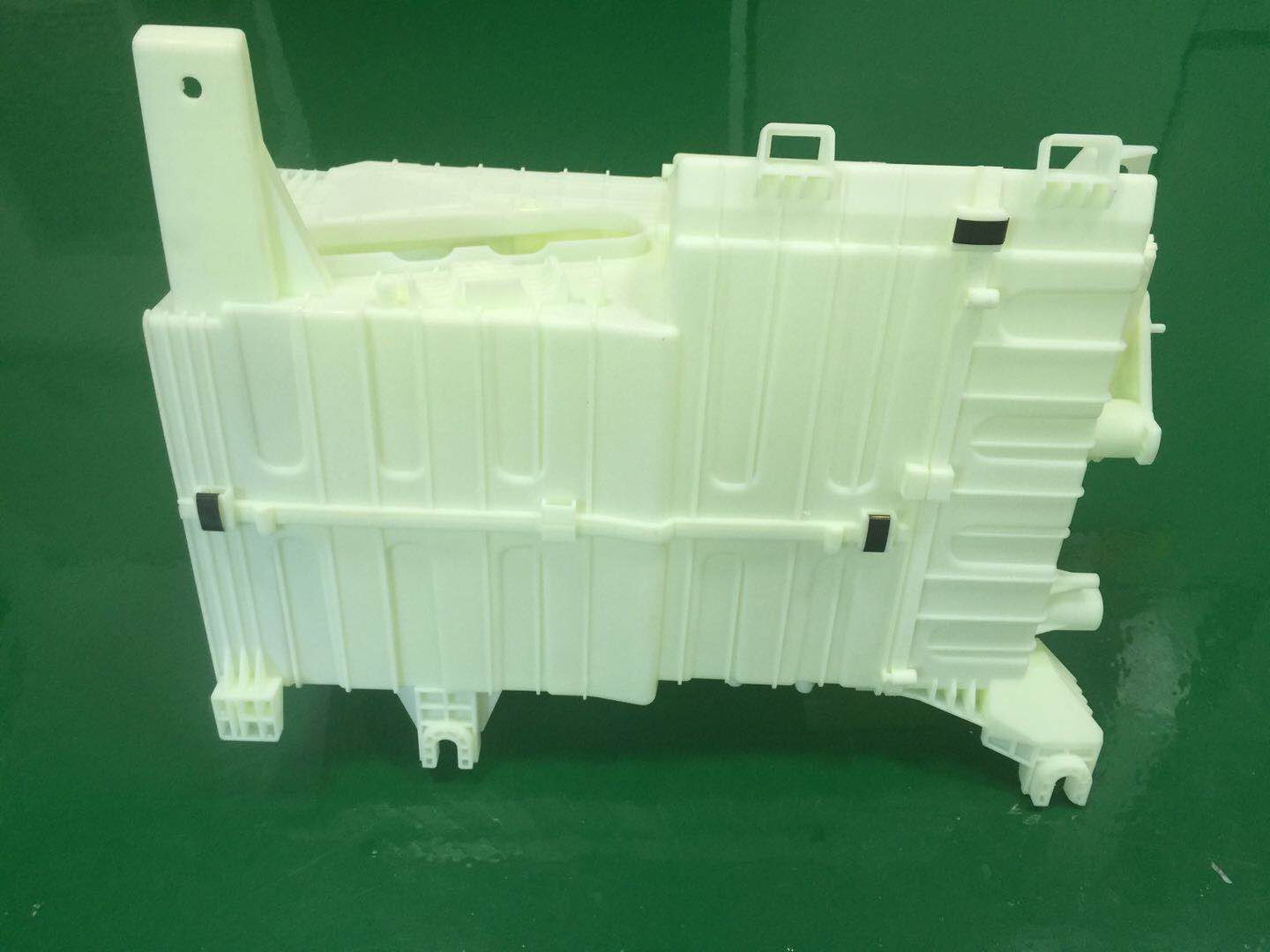

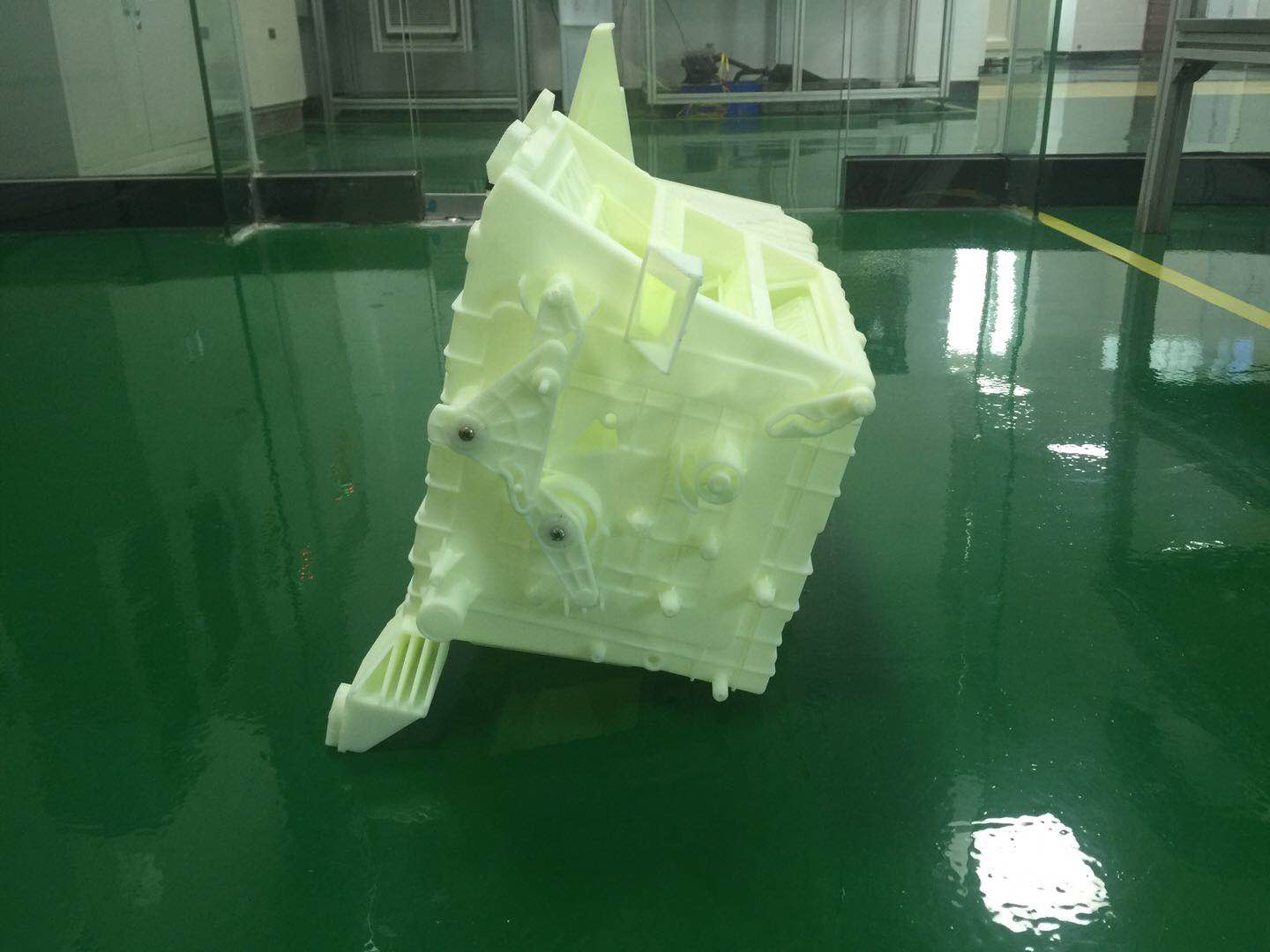

- Ënnert der Hood Komponent Testen

-Héich Temperatur RTV molding

-Windtunnel Testen

- Beliichtungsarmatur Testen

-Komposit Autoklave Tooling

-HVAC Komponent Testen

-Intake Manifold Testen

- Orthodontik

Applikatioun Felder

Educatioun

Hand Schimmel

Auto Deeler

Verpakung Design

Art Design

Medizinesch

physesch Eegeschaften (Flëssegkeet)

| Ausgesinn | wäiss |

| Dicht | 1,13 g/cm3@25 ℃ |

| Viskositéit | 400~480 cps @ 29 ℃ |

| Dp | 0,152 mm |

| Ec | 7,6 mJ/cm2 |

| Bauschichtdicke | 0,05 ~ 0,12 mm |

MECHANICAL PROPERTIES (POST-CURED)

| Miessung | Test Method | Wäert | |

| 90-Minute UV Post-Kur | 90-Minute UV +2 Stonnen @ 160 ℃ thermesch Post-Kur | ||

| Hardness, Shore D | ASTM D 2240 | 87 | 91 |

| Flexural Modulus, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Flexural Stäerkt, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Tensile Modulus, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Spannkraaft, MPa | ASTM D 638 | 58-67 | 50-62 |

| Verlängerung bei der Paus | ASTM D 638 | 4-8% | 4-6% |

| Schlagkraaft, geschniddene lzod, J/m | ASTM D 256 | 18-30 | 16-23 |

| Hëtzt Oflenkungstemperatur, ℃ | ASTM D 648 @66PSI | 81 | 98 |

| Glas Iwwergang, Tg, ℃ | DMA, Ech | 100 | 111 |

| Wärmeexpansiounskoeffizient, E6/℃ | TMA (T | 79 | 86 |

| Wärmeleitung, W/m.℃ | 0,171 | ||

| Dicht | 1.24 | ||

| Waasser Absorptioun | ASTM D 570-98 | 0,49% | 0,46% |

Mechanesch Eegeschafte vun Post-cured Material

| Miessung | TESTMETHODE

|

| WÄRT |

|

|

| 90-Minute UV Post-Kur | 90-Minute UV +2 Stonnen @ 160℃thermeschpost-Kur |

| Hardness, Shore D | ASTM D 2240 | 87 | 91 |

| Flexural Modulus, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Flexural Stäerkt, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Tensile Modulus, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Spannkraaft, MPa | ASTM D 638 | 58-67 | 50-62 |

| Verlängerung bei der Paus | ASTM D 638 | 4-8% | 4-6% |

| Schlagkraaft, geschniddene lzod, J/m

| ASTM D 256

| 18-30 Uhr

| 16-23 |

| Hëtzt Oflehnungstemperatur,℃

| ASTM D 648 @66PSI

| 81 | 98

|

| Glas Transitioun, Tg ,℃ | DMA,E"Héichpunkt

| 100 | 111

|

| Thermesch Expansiounskoeffizient, E6/℃ | TMA(T)

| 79

| 86

|

| Wärmeleitung, W/m.℃ |

| 0,171 |

|

| Dicht |

| 1.24 |

|

| Waasser Absorptioun | ASTM D 570-98 | 0,49% | 0,46% |