Rezin SZUV-T1120-wo rezistans tanperati

Entwodiksyon jeneral

Karakteristik:

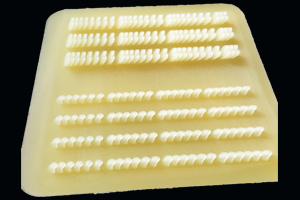

SZUV -T1120 se yon résine SL jòn ki gen pèfòmans tèmik inegal. Li ka kenbe tèt ak tanperati ki depase 200 ℃ nan yon ti tan ak 120 ℃ nan yon tan long. Li fèt pou manyen yon gran varyete aplikasyon pou tanperati ki wo ak tès negatif.

Karakteristik tipik

Segondè fòs ak bon rezistans

SZUV-T1120 ka leve kanpe imidite, dlo ak solvants, tankou gazolin, likid transmisyon, lwil oliv ak awozaj. Avèk rezistans chalè san parèy li yo, li apwopriye pou koule, HVAC, ekleraj, zouti, bòdi ak aplikasyon pou tès van.

-Konstwi pi vit epi devlope pi vit

Lè yo bay pwodiksyon rapid ak pati ak yon sifas ki lis, fasil-a-manyen, SZUV-T1120 ka fini pwojè ou a soti nan desen ak tès pati nan tan ki pi kout la.

Ka Aplikasyon

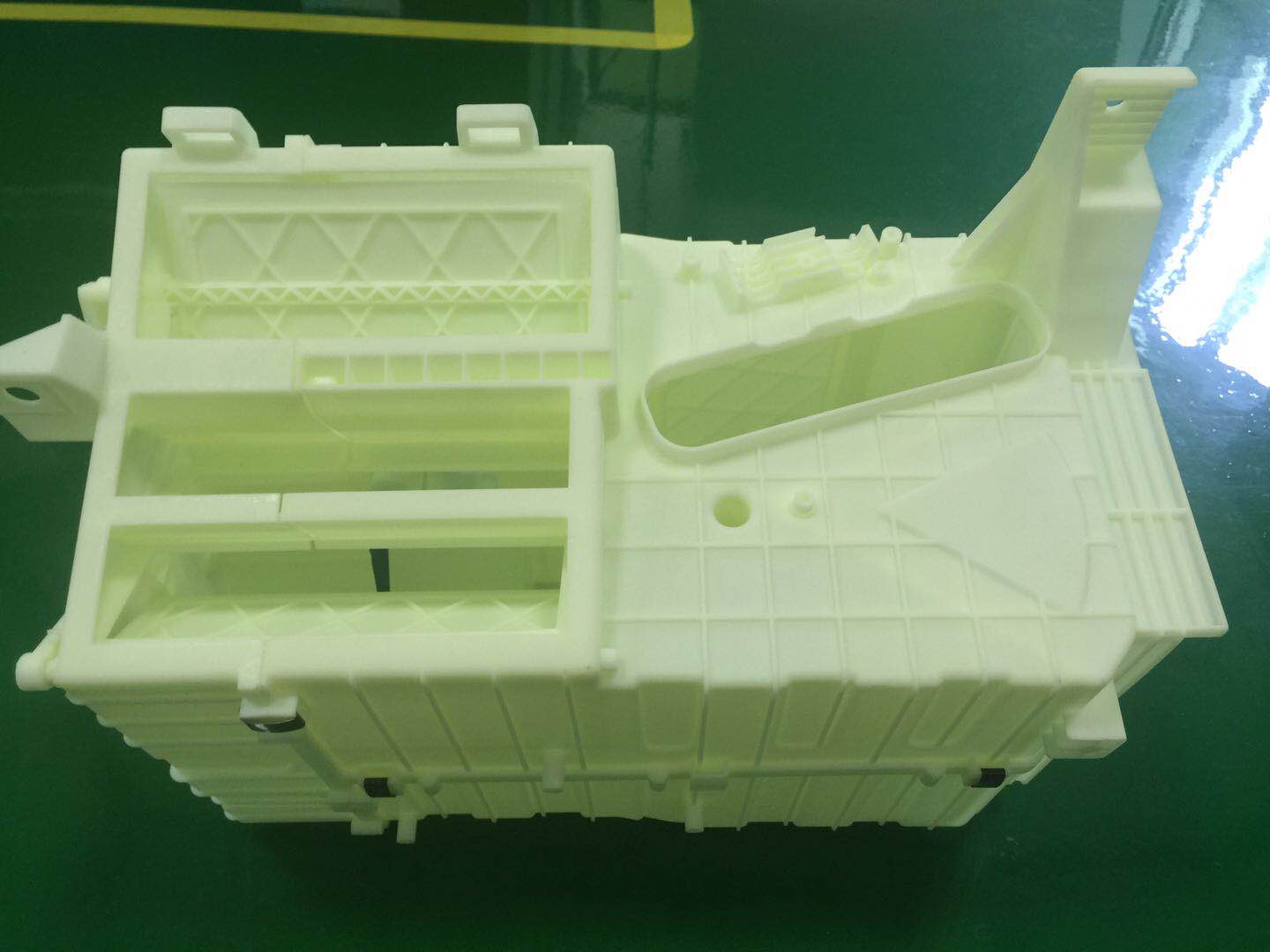

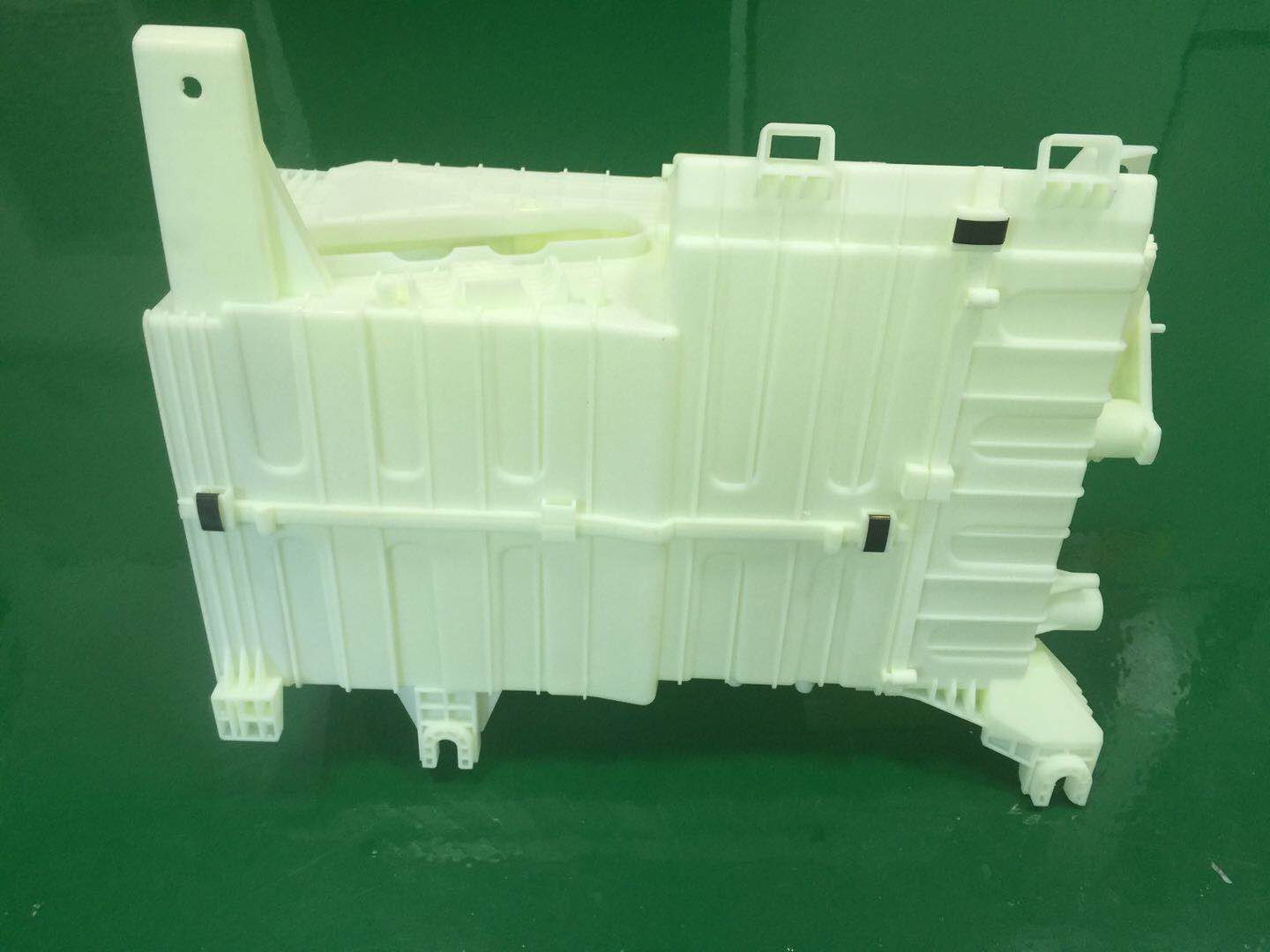

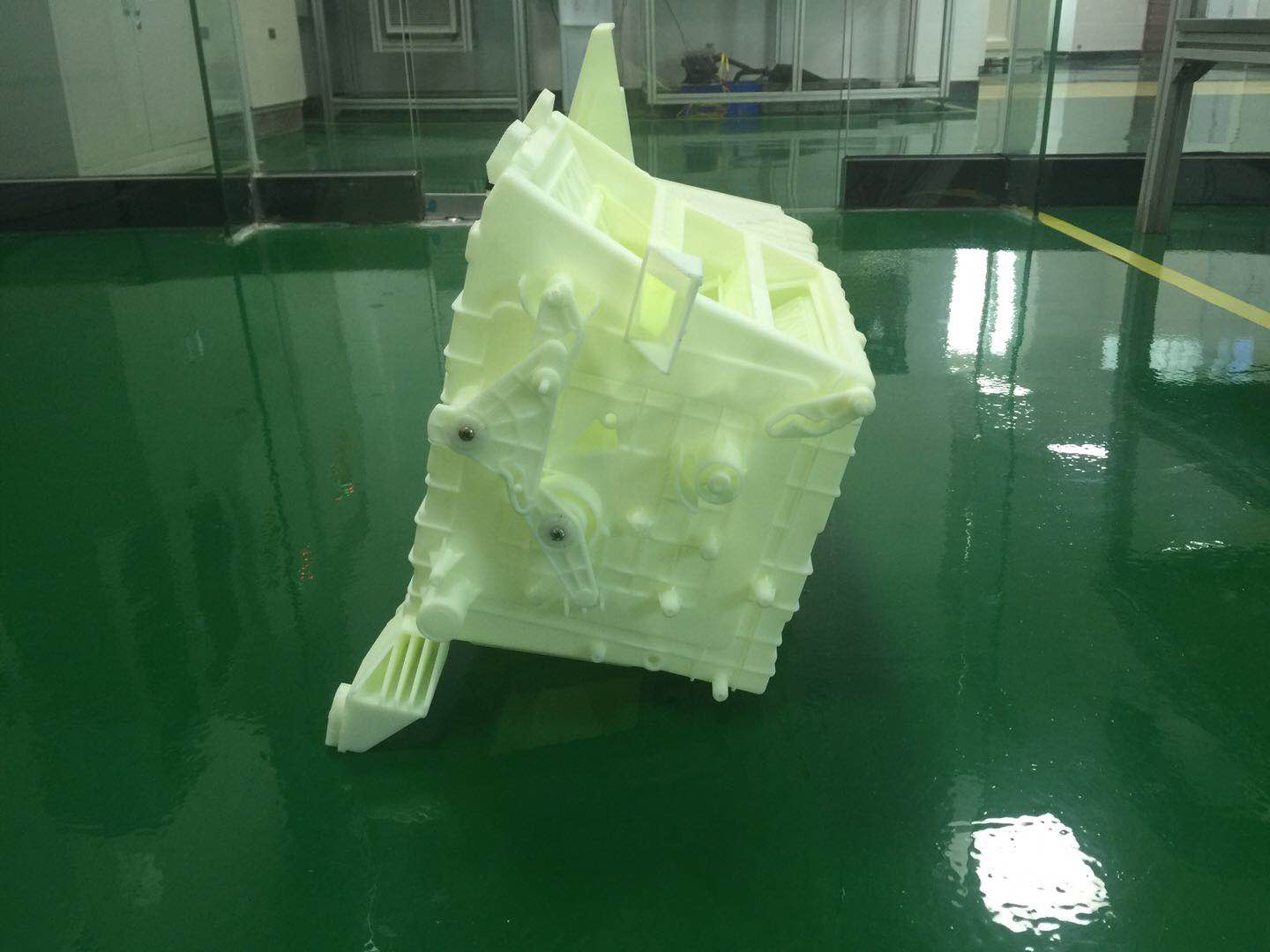

-Anba-kapo eleman tès la

-High tanperati bòdi RTV

-Tès tinèl van

-Tès aparèy ekleraj

-Konpoze otoklav zouti

-Tès eleman HVAC

-Tès manifoul admisyon

-Òtodontik

DOMEN APLIKASYON

Edikasyon

Mwazi men

Pati oto

Konsepsyon anbalaj

Atizay Design

Medikal

PWOPRIYETE FIZIK (LIKID)

| Aparans | blan |

| Dansite | 1.13g/cm3@ 25 ℃ |

| Viskozite | 400 ~ 480 cps @ 29 ℃ |

| Dp | 0.152mm |

| Ec | 7.6 mJ/cm2 |

| Bati epesè kouch | 0.05 ~ 0.12mm |

PWOPRIYETE MEKANIK (POST-GURID)

| Mezi | Metòd tès | Valè | |

| 90 minit UV apre-geri | 90 minit UV + 2 èdtan @ 160 ℃ tèmik apre-geri | ||

| Dite, Shore D | ASTM D 2240 | 87 | 91 |

| Flexural modil, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Fòs flexural, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Modil tensile, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Fòs rupture, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongasyon nan repo | ASTM D 638 | 4-8% | 4-6% |

| Fòs enpak, antay lzod, J/m | ASTM D 256 | 18-30 | 16-23 |

| Tanperati defleksyon chalè, ℃ | ASTM D 648 @66PSI | 81 | 98 |

| Tranzisyon vè, Tg, ℃ | DMA,E'peak | 100 | 111 |

| Koefisyan ekspansyon tèmik, E6/℃ | TMA(T | 79 | 86 |

| Konduktivite tèmik, W/m.℃ | 0.171 | ||

| Dansite | 1.24 | ||

| Absòpsyon dlo | ASTM D 570-98 | 0.49% | 0.46% |

Pwopriyete mekanik nan materyèl apre-geri

| MEZI | METÒD TÈS

|

| VALÈ |

|

|

| 90 minit UV apre-geri | 90-minit UV + 2 èdtan @ 160℃tèmikapre-geri |

| Dite, Shore D | ASTM D 2240 | 87 | 91 |

| Flexural modil, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Fòs flexural, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Modil tensile, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Fòs rupture, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongasyon nan repo | ASTM D 638 | 4-8% | 4-6% |

| Fòs enpak, antay lzod, J/m

| ASTM D 256

| 18 ~ 30

| 16 ~ 23 |

| Tanperati defleksyon chalè,℃

| ASTM D 648 @66PSI

| 81 | 98

|

| Tranzisyon vè, Tg ,℃ | DMA,E”pik

| 100 | 111

|

| Koefisyan ekspansyon tèmik, E6/℃ | TMA(T)

| 79

| 86

|

| Tèmik konduktiviti, W/m.℃ |

| 0.171 |

|

| Dansite |

| 1.24 |

|

| Absòpsyon dlo | ASTM D 570-98 | 0.49% | 0.46% |