Resin SZUV-T1120-tahan suhu dhuwur

Pambuka Umum

ciri:

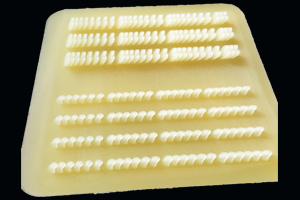

SZUV -T1120 punika resin SL kuning kang wis kinerja termal unmatched. Bisa tahan suhu luwih saka 200 ℃ ing wektu cendhak lan 120 ℃ ing dangu. Iki dirancang kanggo nangani macem-macem suhu dhuwur lan aplikasi testing salabetipun.

Fitur khas

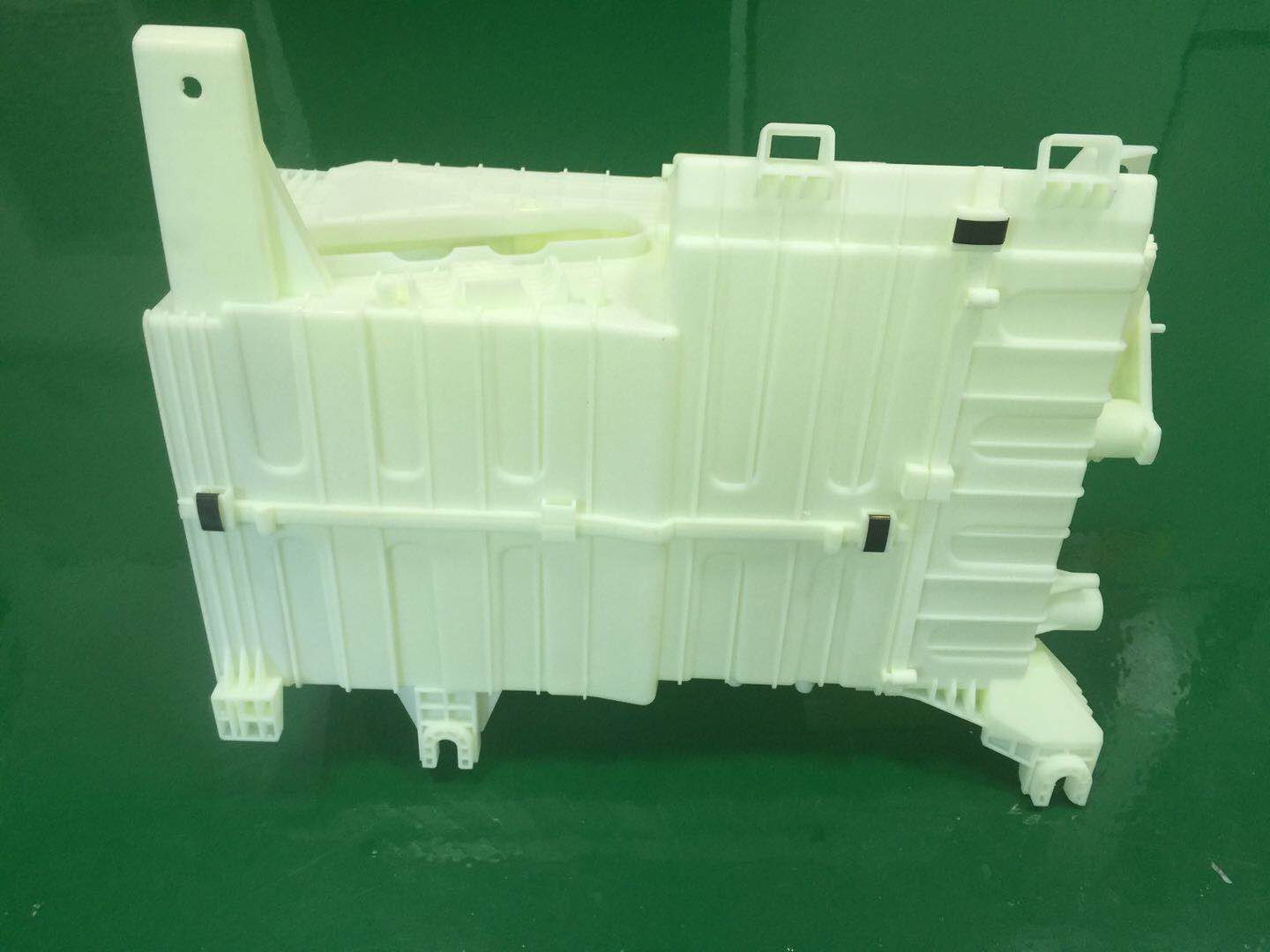

KEKUATAN HIGH lan RESISTANCE apik

SZUV-T1120 bisa tahan kelembapan, banyu lan pelarut, kayata bensin, cairan transmisi, lenga lan coolant. Kanthi resistensi panas sing ora cocog, cocog kanggo aplikasi tes aliran, HVAC, lampu, perkakas, cetakan lan tes trowongan angin.

- Mbangun luwih cepet lan berkembang luwih cepet

Kanthi nyedhiyakake output lan bagean sing cepet kanthi permukaan sing alus lan gampang ditangani, SZUV-T1120 bisa ngrampungake proyek sampeyan saka nggambar nganti nyoba bagean ing wektu paling cendhak.

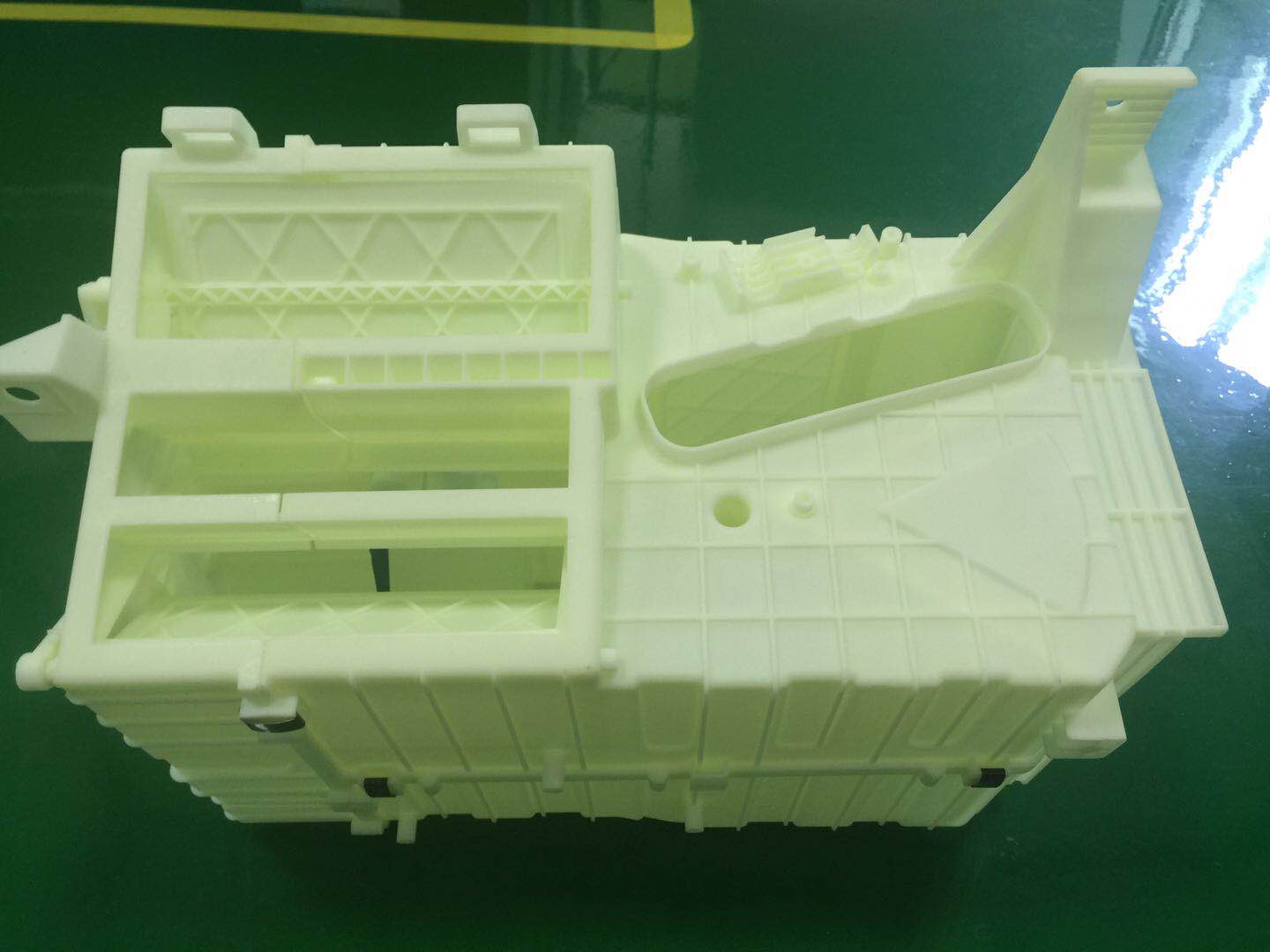

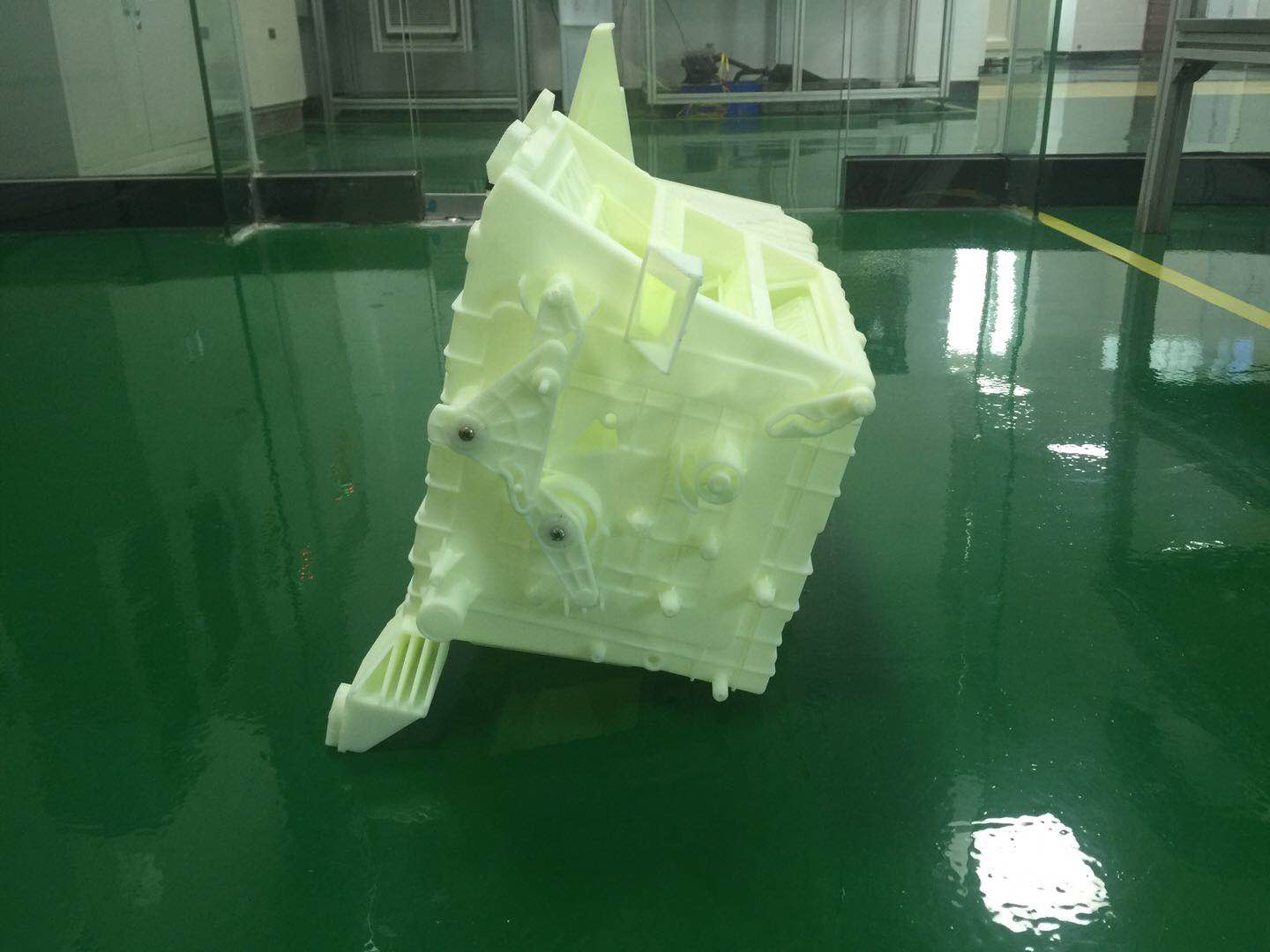

Kasus Aplikasi

- Uji coba komponen ing ngisor tutup

-Molding RTV suhu dhuwur

- Pengujian terowongan angin

- Pengujian lampu

- Perkakas autoclave komposit

- Pengujian komponen HVAC

- Pengujian intake manifold

- Ortodontik

LAPANGAN APLIKASI

Pendidikan

Cetakan Tangan

Auto Parts

Desain Kemasan

Seni Desain

medis

SIFAT FISIK (CAIR)

| Penampilan | putih |

| Kapadhetan | 1,13 g/cm3@ 25 ℃ |

| Viskositas | 400~480 cps @ 29 ℃ |

| Dp | 0,152 mm |

| Ec | 7,6 mJ/cm2 |

| Ketebalan lapisan bangunan | 0,05 ~ 0,12 mm |

SIFAT MEKANIKAL (POST-CURED)

| Pangukuran | Metode Tes | Nilai | |

| 90-menit UV pasca-tamba | 90 menit UV + 2 jam @ 160 ℃ termal pasca-tamba | ||

| Hardness, Shore D | ASTM D 2240 | 87 | 91 |

| Modulus lentur, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Kekuatan lentur, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Modulus tarik, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Kekuatan tarik, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation ing break | ASTM D 638 | 4-8% | 4-6% |

| Kekuwatan impact, notched lzod, J/m | ASTM D 256 | 18-30 | 16-23 |

| Suhu defleksi panas, ℃ | ASTM D 648 @66PSI | 81 | 98 |

| Transisi kaca, Tg, ℃ | DMA, E'peak | 100 | 111 |

| Koefisien ekspansi termal, E6 / ℃ | TMA (T | 79 | 86 |

| Konduktivitas termal, W/m. ℃ | 0.171 | ||

| Kapadhetan | 1.24 | ||

| panyerepan banyu | ASTM D 570-98 | 0,49% | 0,46% |

Sifat Mekanik Bahan Pasca-cured

| PENGUKURAN | METODE UJI

|

| NILAI |

|

|

| 90-menit UV pasca-tamba | 90 menit UV +2 jam@160℃termalsawise-tamba |

| Hardness, Shore D | ASTM D 2240 | 87 | 91 |

| Modulus lentur, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| Kekuatan lentur, Mpa | ASTM D 790 | 60-80 | 90-101 |

| Modulus tarik, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Kekuatan tarik, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation ing break | ASTM D 638 | 4-8% | 4-6% |

| Kekuwatan impact, notched lzod, J/m

| ASTM D 256

| 18~30

| 16~23 |

| Suhu defleksi panas,℃

| ASTM D 648 @66PSI

| 81 | 98

|

| Transisi kaca, Tg ,℃ | DMA,E”puncak

| 100 | 111

|

| Koefisien ekspansi termal, E6/℃ | TMA(T)

| 79

| 86

|

| Konduktivitas termal, W/m.℃ |

| 0.171 |

|

| Kapadhetan |

| 1.24 |

|

| panyerepan banyu | ASTM D 570-98 | 0,49% | 0,46% |