Resini SZUV-T1120-ga otutu resistance

Gbogbogbo Ifihan

Awọn abuda:

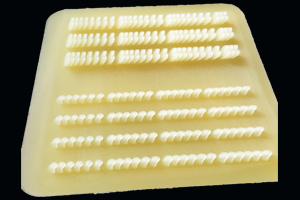

SZUV -T1120 ni a ofeefee SL resini eyi ti o ni unmatched gbona iṣẹ. O le withstand awọn iwọn otutu ni excess ti 200 ℃ ni a kukuru akoko ati 120 ℃ ni igba pipẹ. O ti wa ni apẹrẹ fun mimu kan jakejado orisirisi ti ga otutu ati ikolu ti igbeyewo ohun elo.

Aṣoju awọn ẹya ara ẹrọ

AGBARA GIGA ati IJỌ RERE

SZUV-T1120 le duro soke ọriniinitutu, omi ati nkanmimu, gẹgẹ bi awọn petirolu, gbigbe ito, epo ati coolant. Pẹlu resistance ooru ti ko ni ibamu, o dara fun sisan, HVAC, ina, ohun elo irinṣẹ, mimu ati awọn ohun elo idanwo oju eefin afẹfẹ.

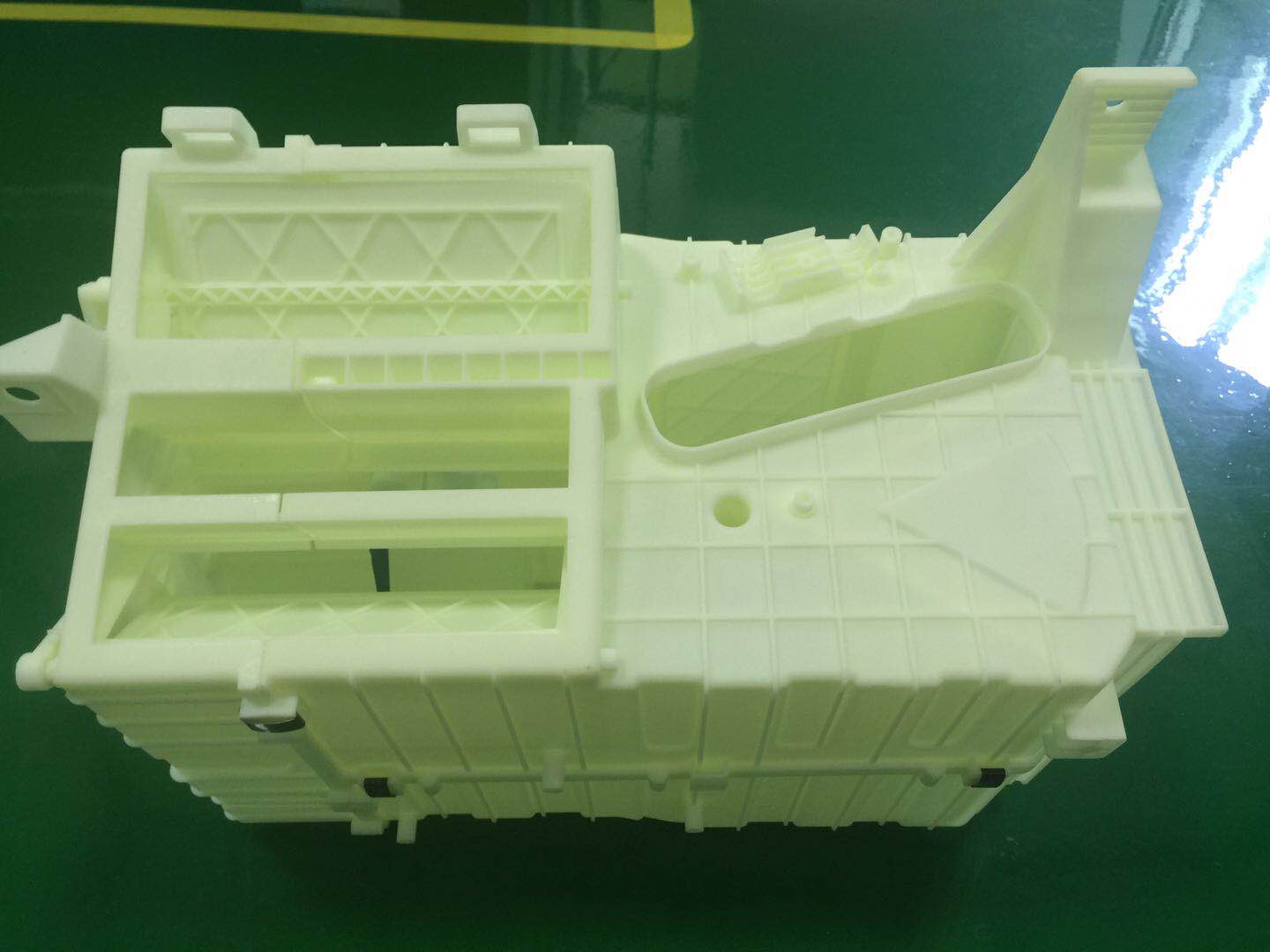

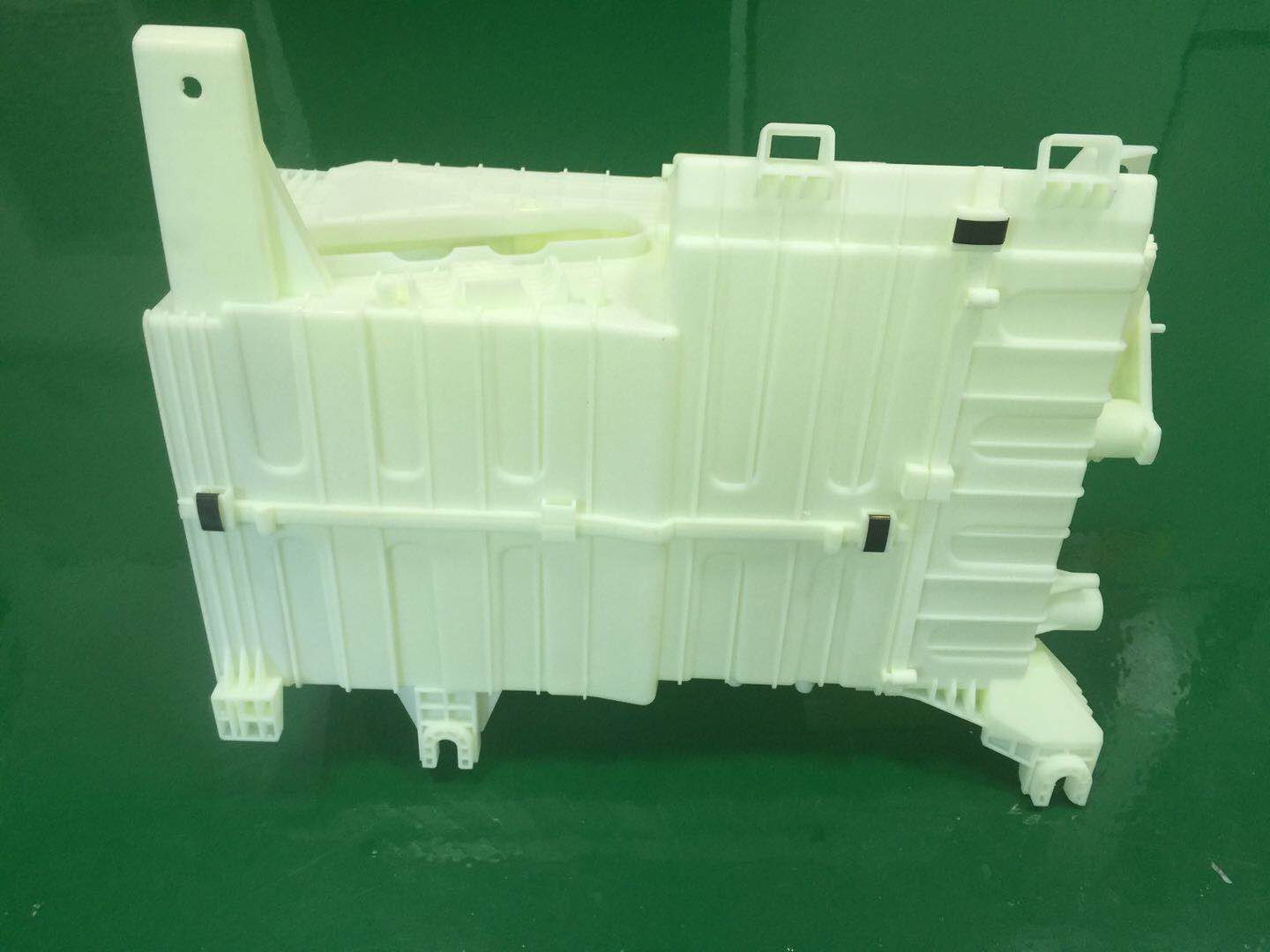

-KỌ FASTER ati Dagbasoke FASTER

Nipa ipese iṣelọpọ iyara ati awọn ẹya pẹlu didan, irọrun-lati mu dada, SZUV-T1120 le pari iṣẹ akanṣe rẹ lati iyaworan si awọn apakan idanwo ni akoko kukuru.

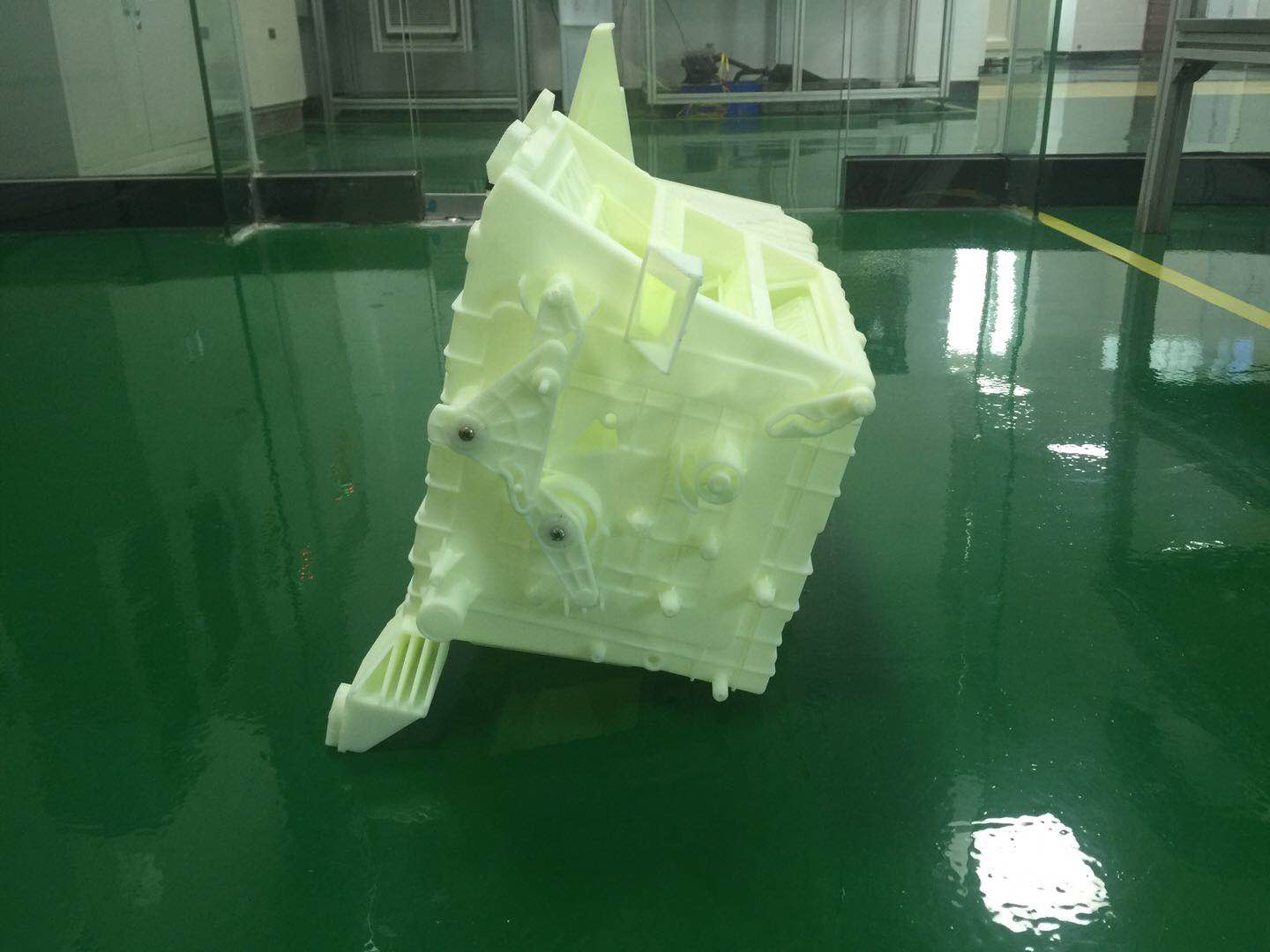

Awọn ọran Ohun elo

-Labẹ- Hood paati igbeyewo

-High otutu RTV igbáti

- Idanwo oju eefin afẹfẹ

-Imọlẹ imuduro igbeyewo

-Akopọ autoclave tooling

-HVAC paati igbeyewo

-Gbigbemi ọpọlọpọ igbeyewo

-Orthodontics

Awọn aaye ohun elo

Ẹkọ

Ọwọ Molds

Awọn ẹya ara ẹrọ laifọwọyi

Apẹrẹ apoti

Apẹrẹ aworan

Iṣoogun

ASEJE ARA (OMI)

| Ifarahan | funfun |

| iwuwo | 1.13g/cm3@ 25 ℃ |

| Igi iki | 400~480 cps @ 29 ℃ |

| Dp | 0.152mm |

| Ec | 7,6 mJ / cm2 |

| Building Layer sisanra | 0.05 ~ 0.12mm |

Awọn ohun-ini ẹrọ (Titun-iwosan lẹhin)

| Wiwọn | Ọna idanwo | Iye | |

| 90-iseju UV lẹhin-ni arowoto | 90-iṣẹju UV +2 wakati @ 160 ℃ igbona lẹhin imularada | ||

| Lile, Shore D | ASTM D2240 | 87 | 91 |

| Modulu Flexural, Mpa | ASTM D790 | 2678-3186 | 3502-3631 |

| Agbara Flexural, Mpa | ASTM D790 | 60-80 | 90-101 |

| Modulu fifẹ, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Agbara fifẹ, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation ni isinmi | ASTM D 638 | 4-8% | 4-6% |

| Agbara ipa, ogbontarigi lzod, J/m | ASTM D256 | 18-30 | 16-23 |

| Ooru yiyọ kuro ni iwọn otutu, ℃ | ASTM D 648 @ 66PSI | 81 | 98 |

| Gilasi iyipada, Tg, ℃ | DMA, ga | 100 | 111 |

| Olusọdipúpọ ti imugboroosi gbona, E6/℃ | TMA (T | 79 | 86 |

| Imudara igbona, W/m.℃ | 0.171 | ||

| iwuwo | 1.24 | ||

| Gbigba omi | ASTM D 570-98 | 0.49% | 0.46% |

Awọn ohun-ini ẹrọ ti Ohun elo Itọju-lẹhin

| ODIwọn | ONA idanwo

|

| IYE |

|

|

| 90-iseju UV lẹhin-ni arowoto | 90-iseju UV +2 wakati @ 160℃gbonalẹhin-iwosan |

| Lile, Shore D | ASTM D2240 | 87 | 91 |

| Modulu Flexural, Mpa | ASTM D790 | 2678-3186 | 3502-3631 |

| Agbara Flexural, Mpa | ASTM D790 | 60-80 | 90-101 |

| Modulu fifẹ, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Agbara fifẹ, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation ni isinmi | ASTM D 638 | 4-8% | 4-6% |

| Agbara ipa, ogbontarigi lzod, J/m

| ASTM D256

| 18-30

| 16–23 |

| Awọn iwọn otutu iyipada ooru,℃

| ASTM D 648 @ 66PSI

| 81 | 98

|

| Gilasi iyipada, Tg ,℃ | DMA,E”tente oke

| 100 | 111

|

| Olusọdipúpọ ti imugboroosi igbona, E6/℃ | TMA(T)

| 79

| 86

|

| Ooru elekitiriki, W/m.℃ |

| 0.171 |

|

| iwuwo |

| 1.24 |

|

| Gbigba omi | ASTM D 570-98 | 0.49% | 0.46% |