Résin SZUV-T1120-tahan suhu luhur

Bubuka umum

ciri:

SZUV -T1120 mangrupakeun résin SL konéng nu boga kinerja termal unmatched. Éta tiasa tahan suhu langkung ti 200 ℃ dina waktos anu pondok sareng 120 ℃ kanggo waktos anu lami. Hal ieu dirarancang pikeun nanganan rupa-rupa suhu luhur sareng aplikasi uji anu ngarugikeun.

Fitur has

Kakuatan TINGGI jeung tahan alus

SZUV-T1120 bisa nangtung nepi kalembaban, cai jeung pangleyur, kayaning béngsin, cairan transmisi, minyak jeung coolant. Kalawan lalawanan panas unmatched anak, éta cocog pikeun aliran, HVAC, cahaya, tooling, molding sarta aplikasi nguji torowongan angin.

- Bangun langkung gancang sareng mekarkeun langkung gancang

Ku nyadiakeun kaluaran gancang jeung bagian kalawan permukaan lemes, gampang-to-nanganan, SZUV-T1120 bisa pagawean proyék anjeun ti ngagambar keur nguji bagian dina waktu shortest.

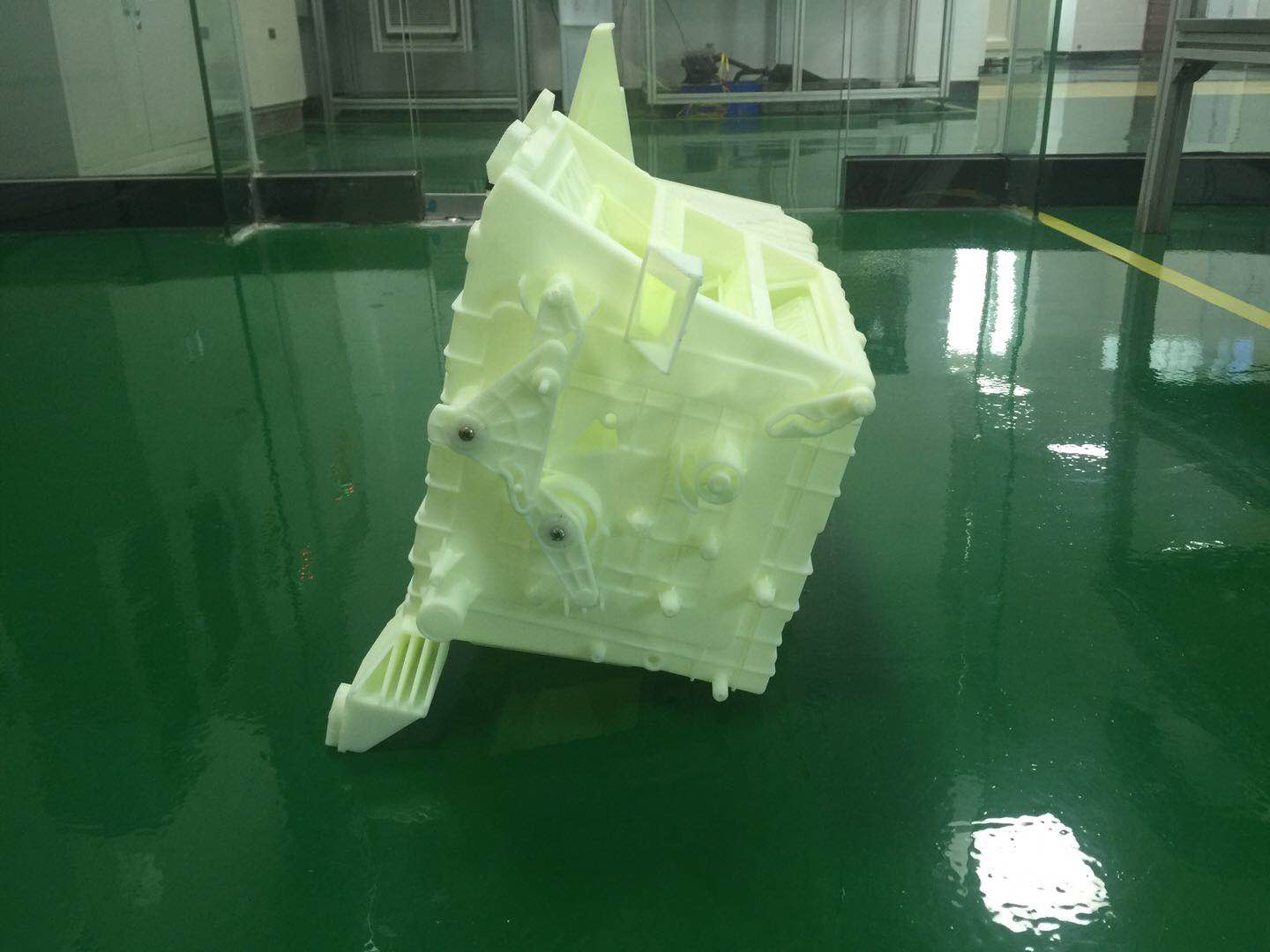

Kasus Aplikasi

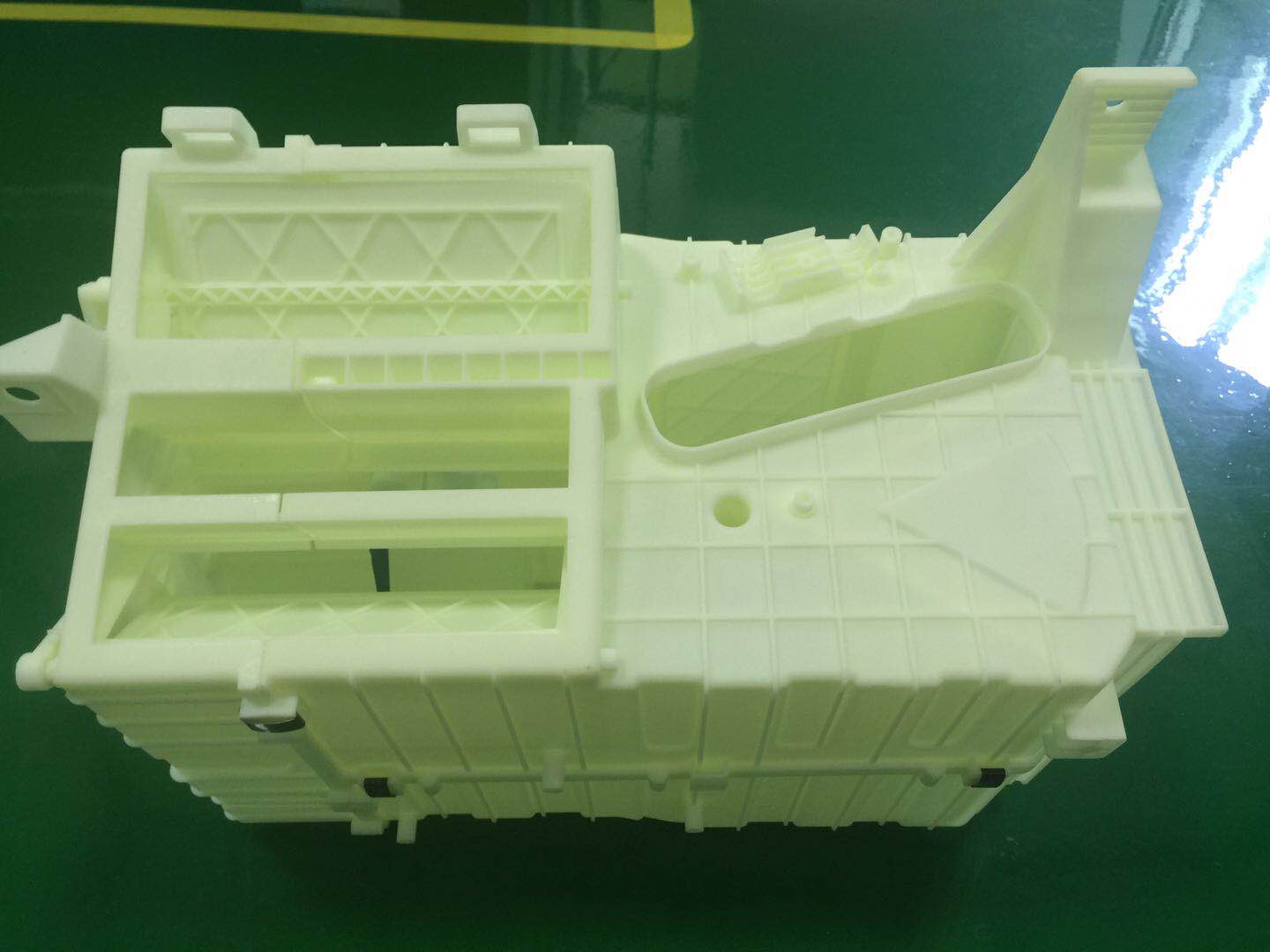

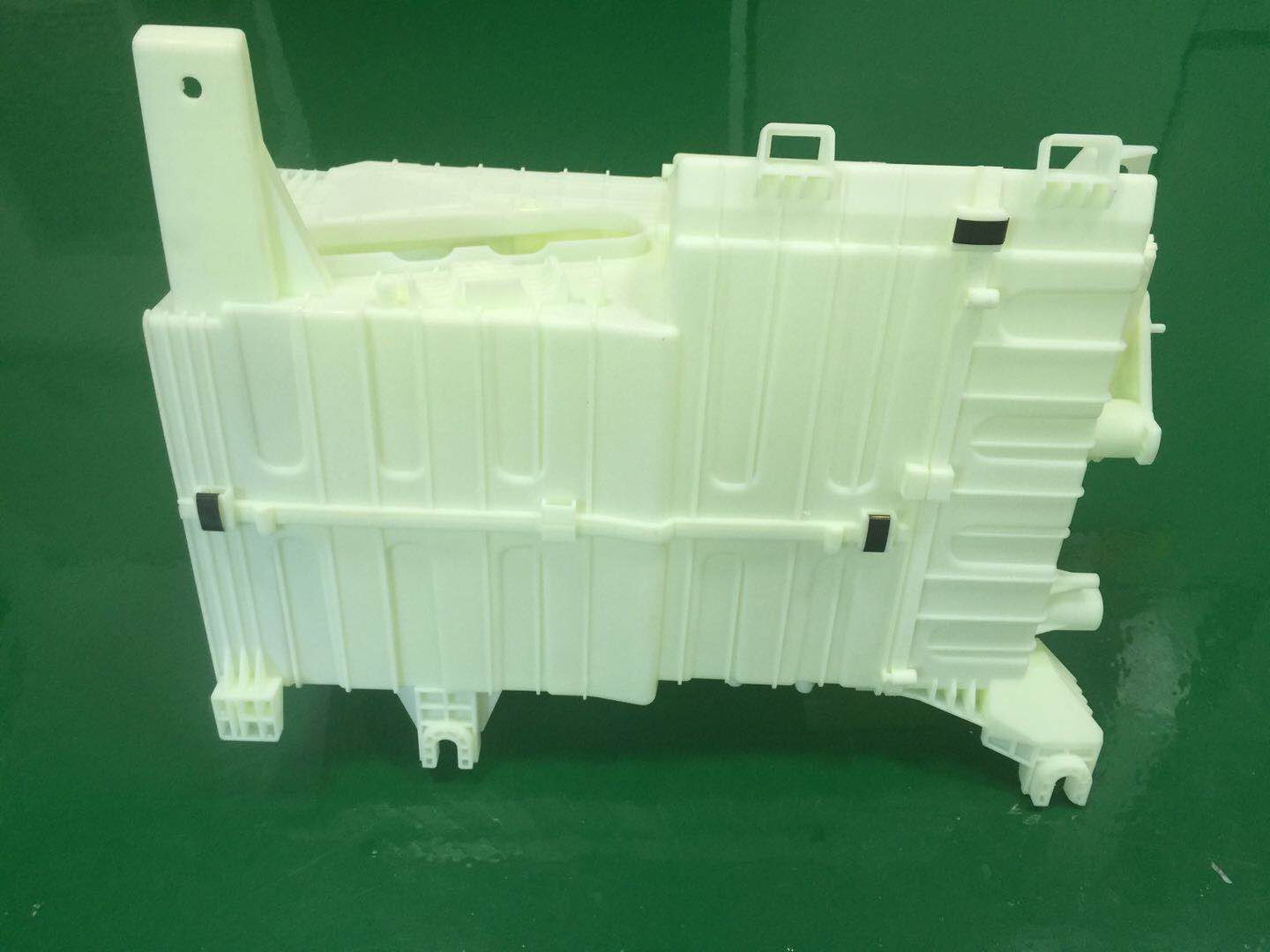

-Uji komponén di handapeun tiung

-Suhu luhur RTV molding

- Ujian torowongan angin

- Uji coba lampu

- Perkakas autoclave komposit

- Uji komponén HVAC

- Uji intake manifold

- Ortodontik

Widang APLIKASI

Atikan

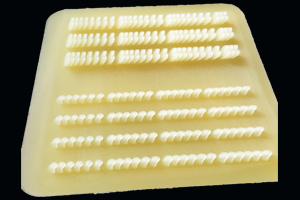

Leungeun Molds

Suku Cadang Mobil

Desain bungkusan

Desain Seni

Médis

SIFAT FISIK (CAIR)

| Penampilan | bodas |

| Kapadetan | 1,13 g/cm3@ 25 ℃ |

| Viskositas | 400~480 cps @ 29 ℃ |

| Dp | 0,152 mm |

| Ec | 7,6 mJ/cm2 |

| Ketebalan lapisan wangunan | 0,05 ~ 0,12 mm |

SIFAT MEKANIKAL (POST-CURED)

| Pangukuran | Métode Tés | Nilai | |

| 90-menit UV post-cure | 90-menit UV + 2 jam @ 160 ℃ termal pos-cageur | ||

| Teuas, Shore D | ASTM D 2240 | 87 | 91 |

| Modulus lentur, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| kakuatan Flexural, Mpa | ASTM D 790 | 60-80 | 90-101 |

| modulus tegangan, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Kakuatan tensile, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation dina putus | ASTM D 638 | 4-8% | 4-6% |

| Kakuatan dampak, notched lzod, J/m | ASTM D 256 | 18-30 | 16-23 |

| Suhu defleksi panas, ℃ | ASTM D 648 @66PSI | 81 | 98 |

| Transisi kaca, Tg, ℃ | DMA, E'puncak | 100 | 111 |

| Koéfisién ékspansi termal, E6 / ℃ | TMA (T | 79 | 86 |

| konduktivitas termal, W / m. ℃ | 0.171 | ||

| Kapadetan | 1.24 | ||

| Nyerep cai | ASTM D 570-98 | 0,49% | 0,46% |

Sipat mékanis tina Bahan Post-Cured

| PANGUKURAN | METODE UJI

|

| NILAI |

|

|

| 90-menit UV post-cure | 90-menit UV +2 jam@160℃termalsanggeus-cageur |

| Teuas, Shore D | ASTM D 2240 | 87 | 91 |

| Modulus lentur, Mpa | ASTM D 790 | 2678-3186 | 3502-3631 |

| kakuatan Flexural, Mpa | ASTM D 790 | 60-80 | 90-101 |

| modulus tegangan, MPa | ASTM D 638 | 2840-3113 | 3484-3771 |

| Kakuatan tensile, MPa | ASTM D 638 | 58-67 | 50-62 |

| Elongation dina putus | ASTM D 638 | 4-8% | 4-6% |

| Kakuatan dampak, notched lzod, J/m

| ASTM D 256

| 18~30

| 16~23 |

| Suhu defleksi panas,℃

| ASTM D 648 @66PSI

| 81 | 98

|

| Transisi kaca, Tg ,℃ | DMA,E”puncak

| 100 | 111

|

| Koéfisién ékspansi termal, E6/℃ | TMA(T)

| 79

| 86

|

| konduktivitas termal, W/m.℃ |

| 0.171 |

|

| Kapadetan |

| 1.24 |

|

| Nyerep cai | ASTM D 570-98 | 0,49% | 0,46% |