I-Resin SZUV-T1120-ukumelana nobushushu obuphezulu

Intshayelelo ngokubanzi

Iimpawu:

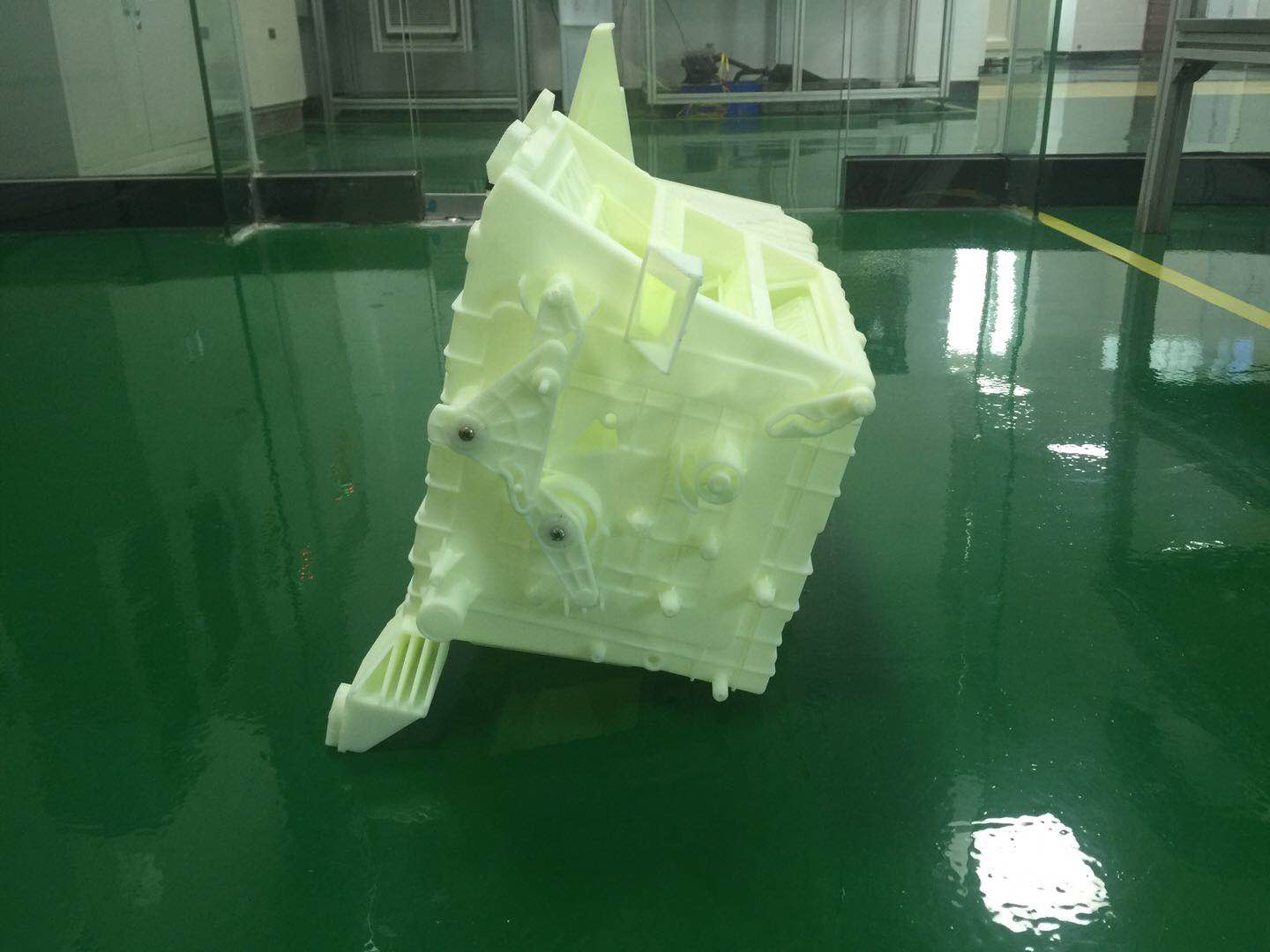

I-SZUV -T1120 yintlaka ye-SL etyheli eye yasebenza ngokungafaniyo ne-thermal. Iyakwazi ukumelana namaqondo obushushu angaphaya kwe 200℃ ngexesha elifutshane kunye ne 120℃ ngexesha elide. Yenzelwe ukuphatha iindidi ezininzi zobushushu obuphezulu kunye nezicelo zovavanyo olubi.

Iimpawu eziqhelekileyo

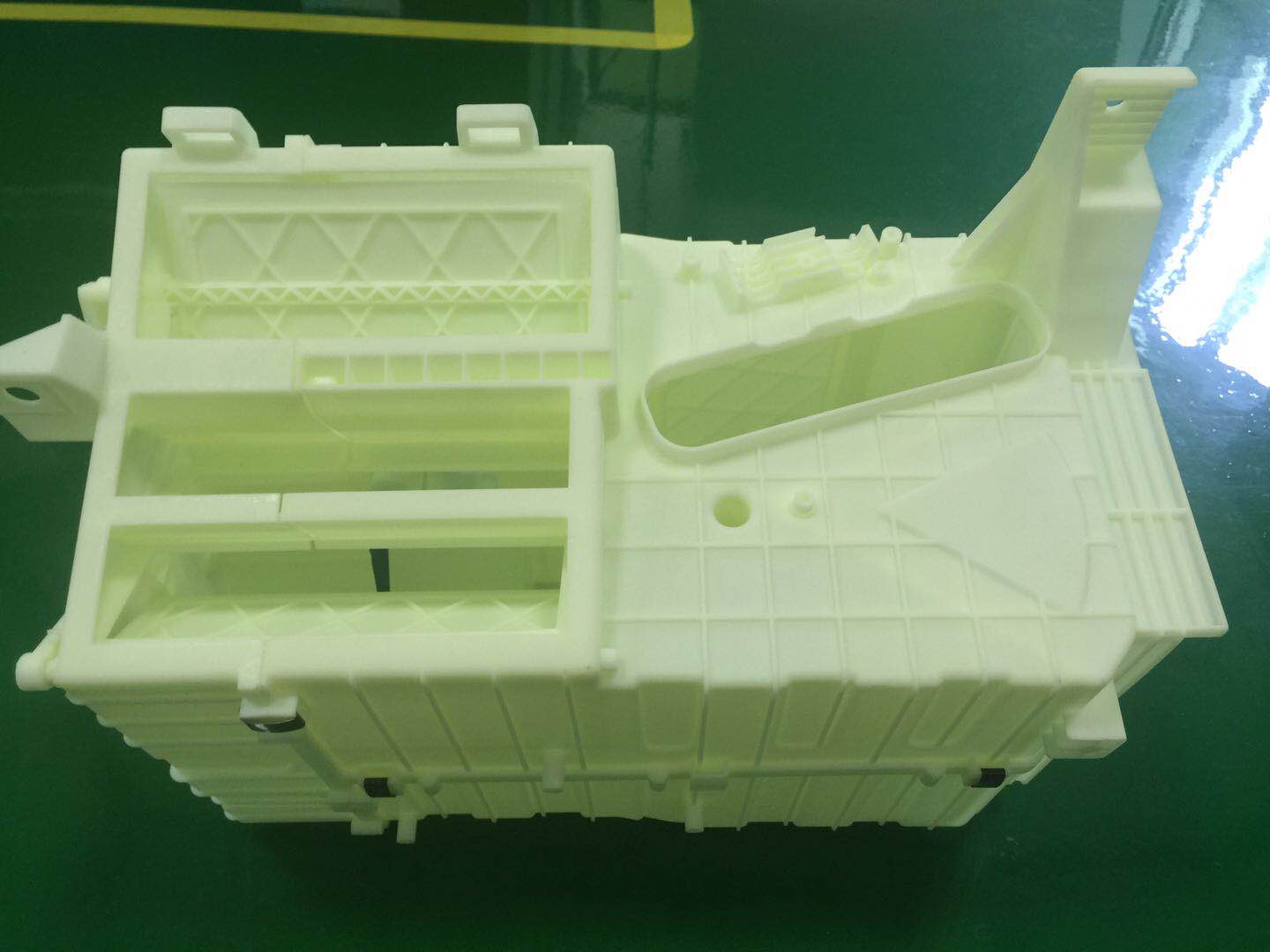

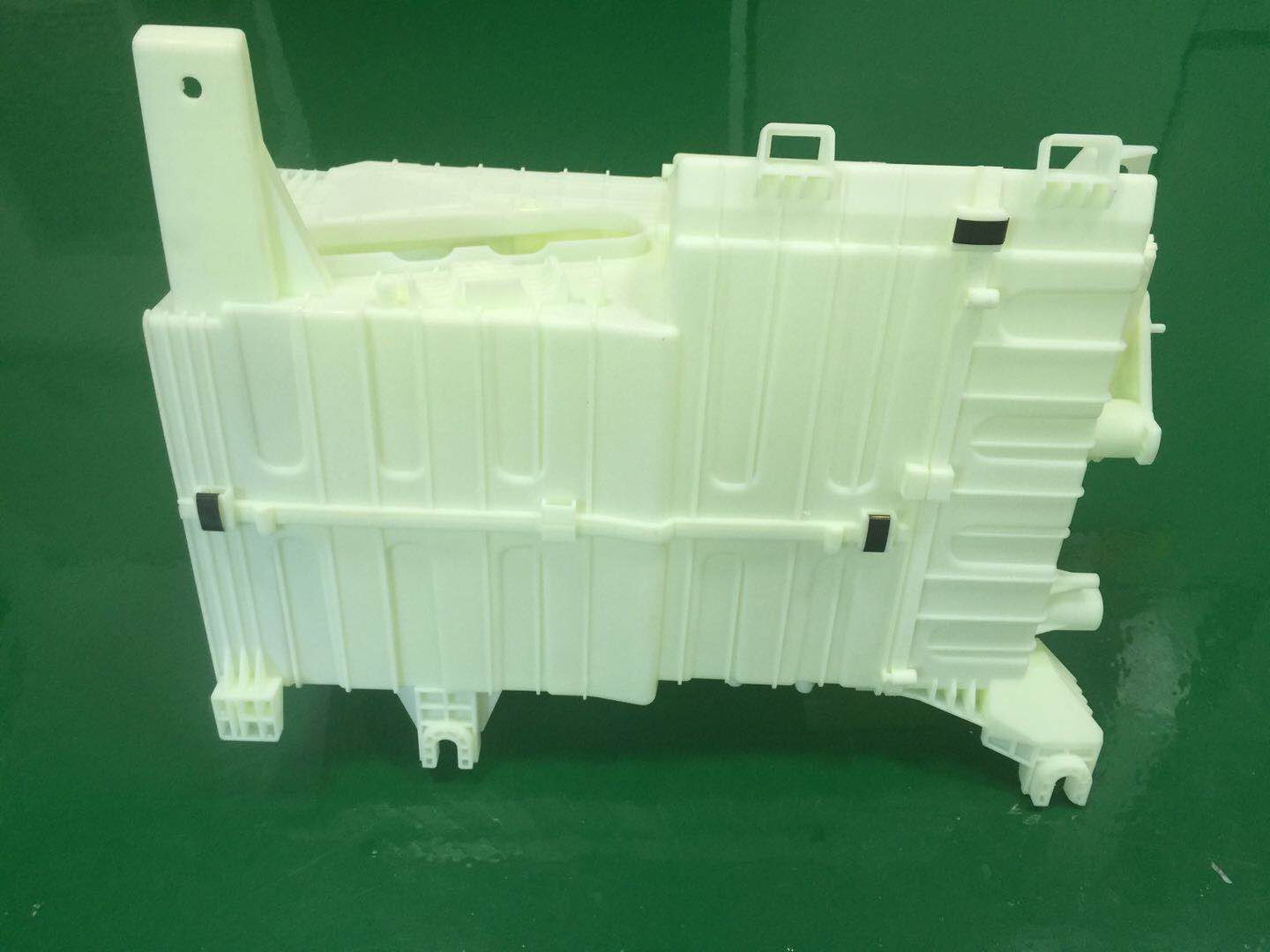

AMANDLA OKUPHEZULU kunye nokuchasana okuhle

I-SZUV-T1120 inokumelana nokufuma, amanzi kunye nezinyibilikisi, ezifana nepetroli, ulwelo lokuhambisa, i-oyile kunye nesipholisi. Ngokumelana nokushisa okungenakulinganiswa, ifanelekile ukuhamba, i-HVAC, ukukhanya, izixhobo, ukubumba kunye nezicelo zokuvavanya itonela yomoya.

-YAKHA NGENXEKO kwaye UPHUHLISE KAKHULU

Ngokubonelela ngemveliso ekhawulezayo kunye neengxenye ezinomgangatho ogudileyo, ekulula ukuwuphatha, i-SZUV-T1120 inokugqiba iprojekthi yakho ukusuka kumzobo ukuya kwiindawo zokuvavanya ngexesha elifutshane.

Iimeko zesicelo

-Uvavanyo lwecandelo phantsi kwe-hood

-Ubushushu obuphezulu bokubumba i-RTV

-Uvavanyo lwetonela yomoya

-Uvavanyo lwezixhobo zokukhanyisa

-Izixhobo ezidibeneyo ze-autoclave

-Uvavanyo lwecandelo le-HVAC

-Uvavanyo oluninzi

-Amathambo

IINDLELA ZOKUSEBENZA

Imfundo

Izandla zokubumba

Amacandelo Auto

Uyilo lokuPakisha

Uyilo lobuGcisa

Ezonyango

IIPROPATI ZOMZIMBA (ULULEKI)

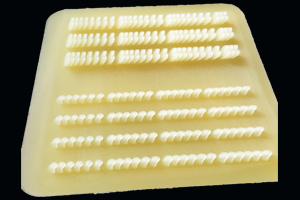

| Imbonakalo | mhlophe |

| Ukuxinana | 1.13g/cm3@ 25 ℃ |

| Viscosity | 400 ~ 480 cps @ 29 ℃ |

| Dp | 0.152mm |

| Ec | 7.6 mJ/cm2 |

| Ubungqingqwa bomaleko wokwakha | 0.05 ~ 0.12mm |

IIPROPATI ZOOMATSHINI (EMVA KOKUPHILA)

| Umlinganiselo | Indlela yoVavanyo | Ixabiso | |

| Imizuzu engama-90 ye-UV emva kokunyanga | Imizuzu engama-90 UV +2 iiyure@160℃ thermal post-cure | ||

| Ubunzima, Unxweme D | I-ASTM D 2240 | 87 | 91 |

| Flexural modulus, Mpa | I-ASTM D 790 | 2678-3186 | 3502-3631 |

| Amandla e-Flexural, uMpa | I-ASTM D 790 | 60-80 | 90-101 |

| Imodyuli yokuqina, iMPa | I-ASTM D 638 | 2840-3113 | 3484-3771 |

| Amandla okuqina, MPa | I-ASTM D 638 | 58-67 | 50-62 |

| Ukwandisa ngexesha lekhefu | I-ASTM D 638 | 4-8% | 4-6% |

| Amandla empembelelo, inotched lzod, J/m | I-ASTM D 256 | 18-30 | 16-23 |

| Ubushushu bokutshintsha ubushushu, ℃ | I-ASTM D 648 @66PSI | 81 | 98 |

| Utshintsho lweglasi, Tg, ℃ | DMA, E'peak | 100 | 111 |

| I-Coefficient yokwandiswa kwe-thermal, E6/℃ | TMA (T | 79 | 86 |

| I-Thermal conductivity, W/m.℃ | 0.171 | ||

| Ukuxinana | 1.24 | ||

| Ukufunxwa kwamanzi | I-ASTM D 570-98 | 0.49% | 0.46% |

IiPropati zoomatshini zeMathiriyeli eNcinyiweyo

| UMLINGANISO | INDLELA YOVAVANYO

|

| VALUE |

|

|

| Imizuzu engama-90 ye-UV emva kokunyanga | Imizuzu engama-90 UV +2 iiyure@160℃thermalemva kokunyanga |

| Ubunzima, Unxweme D | I-ASTM D 2240 | 87 | 91 |

| Flexural modulus, Mpa | I-ASTM D 790 | 2678-3186 | 3502-3631 |

| Amandla e-Flexural, uMpa | I-ASTM D 790 | 60-80 | 90-101 |

| Imodyuli yokuqina, iMPa | I-ASTM D 638 | 2840-3113 | 3484-3771 |

| Amandla okuqina, MPa | I-ASTM D 638 | 58-67 | 50-62 |

| Ukwandisa ngexesha lekhefu | I-ASTM D 638 | 4-8% | 4 -6% |

| Amandla empembelelo, inotched lzod, J/m

| I-ASTM D 256

| 18-30

| 16-23 |

| Ubushushu bokutshintsha ubushushu,℃

| I-ASTM D 648 @66PSI

| 81 | 98

|

| Utshintsho lweglasi,Tg ,℃ | I-DMA,E”incopho

| 100 | 111

|

| I-Coefficient yokwandiswa kwe-thermal, i-E6/℃ | TMA(T)

| 79

| 86

|

| I-Thermal conductivity, W / m.℃ |

| 0.171 |

|

| Ukuxinana |

| 1.24 |

|

| Ukufunxwa kwamanzi | I-ASTM D 570-98 | 0.49% | 0.46% |