Resin SZUV-T1120-elu okpomọkụ na-eguzogide

Okwu mmalite

Njirimara:

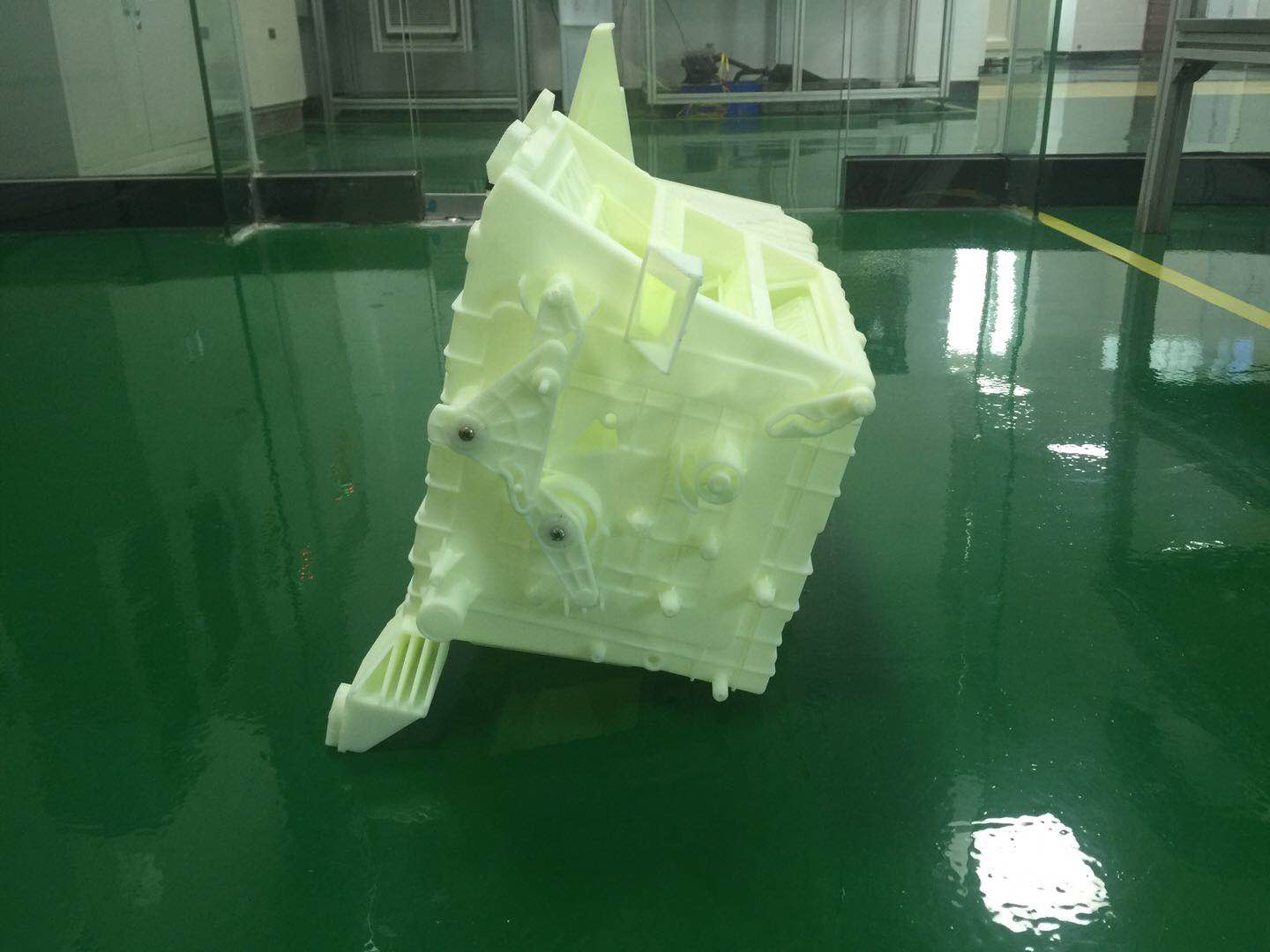

SZUV -T1120 bụ resin SL edo edo nke nwere arụmọrụ ọkụ na-enweghị atụ. Ọ nwere ike idi okpomọkụ karịa 200 ℃ na obere oge na 120 ℃ na ogologo oge. Emebere ya maka ijikwa ụdị okpomọkụ dị iche iche na ngwa nnwale ọjọọ.

Atụmatụ ahụkarị

IKE dị elu na EZIGBO eguzogide

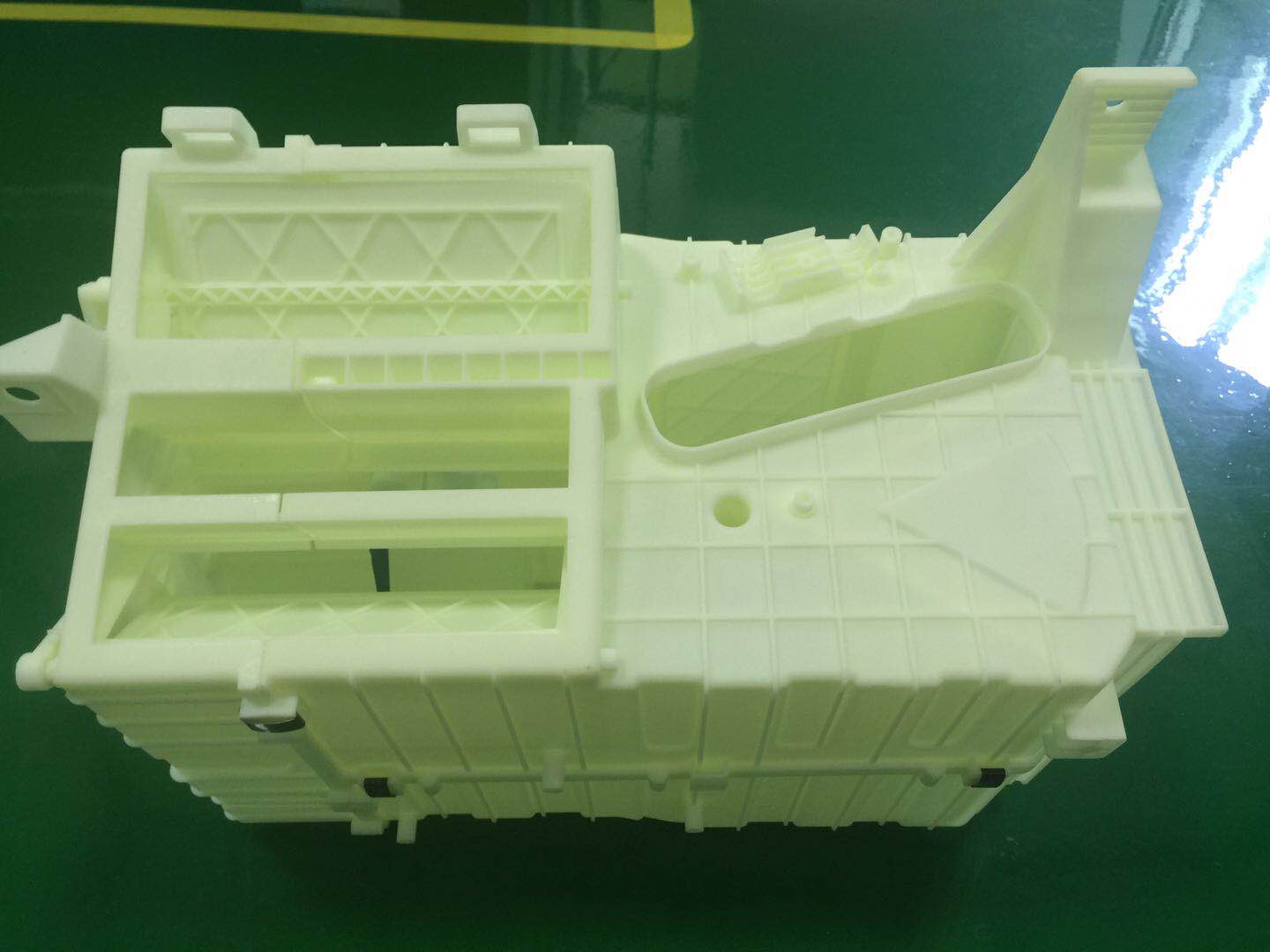

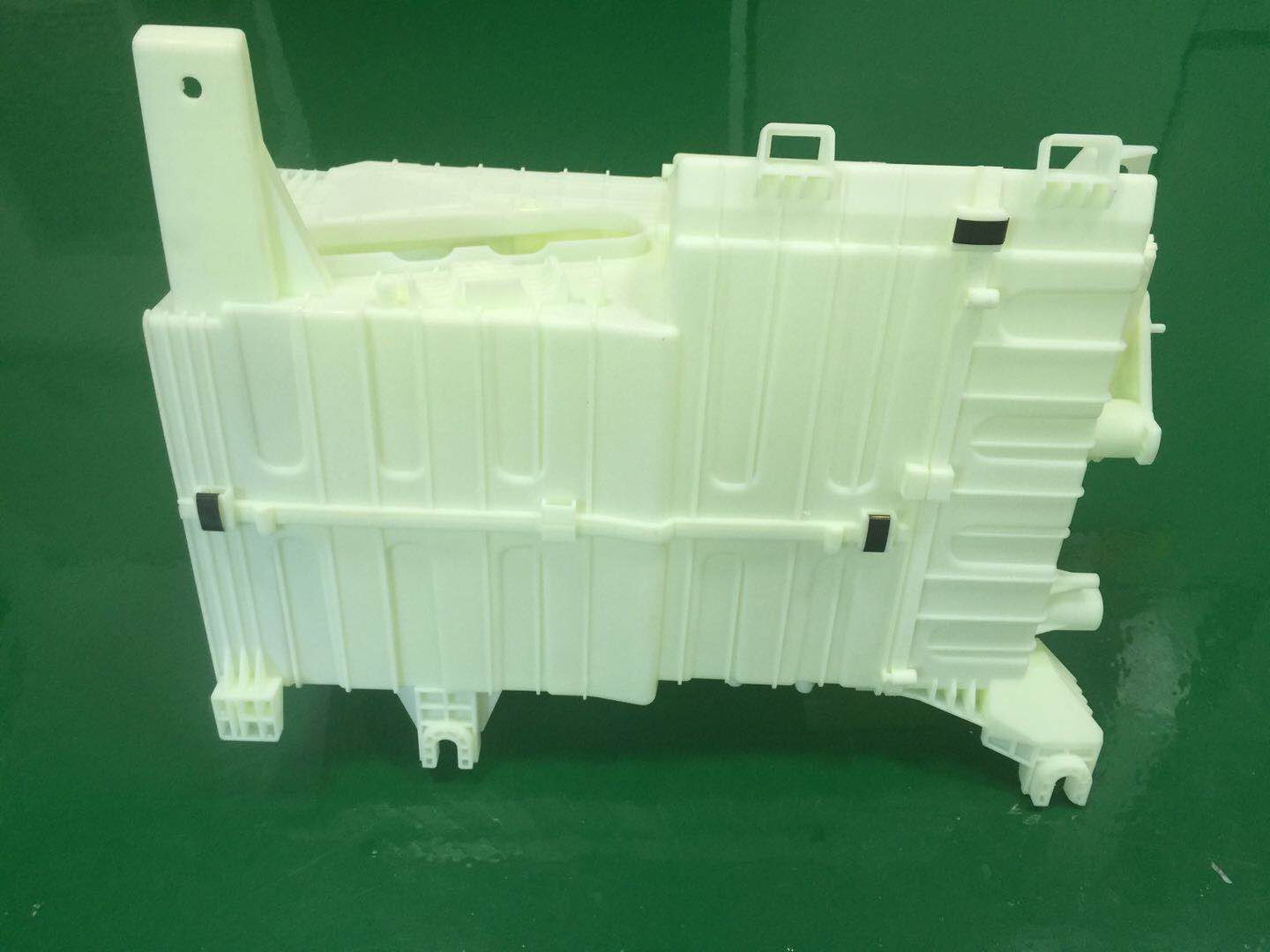

SZUV-T1120 nwere ike iguzo iru mmiri, mmiri na ihe mgbaze, dị ka mmanụ ụgbọala, nnyefe mmiri mmiri, mmanụ na coolant. Site na nguzogide okpomọkụ ya na-enweghị atụ, ọ dabara adaba maka ịgbasa, HVAC, ọkụ, ngwá ọrụ, ịkpụzi na ngwa nyocha ọwara ikuku.

-wulite ngwa ngwa ma zụlite ngwa ngwa

Site n'inye ngwa ngwa ngwa ngwa na akụkụ na elu dị larịị, dị mfe ijikwa, SZUV-T1120 nwere ike imecha ọrụ gị site na ịbịaru na akụkụ ule na obere oge.

Ngwa ngwa

-N'okpuru mkpuchi akụrụngwa nnwale

-Elu okpomọkụ RTV ịkpụzi

-Nnwale ọwara ikuku

-Nnwale ọkụ ọkụ

- Ngwa ọrụ autoclave mejupụtara

-Nnwale akụrụngwa HVAC

-Nnyocha nke ukwuu

- Orthodontics

OGE NKWUKWU

Agụmakwụkwọ

Akpụkpọ aka

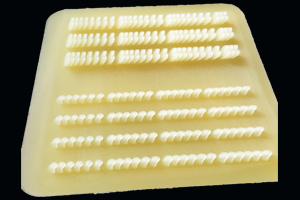

Akụkụ akpaaka

Nkwakọ ngwaahịa

Nhazi nka

Ọgwụ

AKỤRỤ ARỤ AHỤ (mmiri)

| Ọdịdị | ọcha |

| Njupụta | 1.13g / cm3@ 25 ℃ |

| Viscosity | 400~480 cps @ 29 ℃ |

| Dp | 0.152 mm |

| Ec | 7.6mJ/cm2 |

| Ụlọ oyi akwa ọkpụrụkpụ | 0.05 ~ 0.12mm |

AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊ

| Ntụ | Usoro ule | Uru | |

| Ngwọta UV nke nkeji 90 | 90-nkeji UV +2 awa @ 160 ℃ ọgwụgwọ ọkụ gachara | ||

| Hardness, Shore D | ASTM D2240 | 87 | 91 |

| Mgbanwe mgbanwe, Mpa | ASTM D790 | 2678-3186 | 3502-3631 |

| Ike mgbanwe, Mpa | ASTM D790 | 60-80 | 90-101 |

| modul tensile, MPa | ASTM D638 | 2840-3113 | 3484-3771 |

| Ike tensile, MPa | ASTM D638 | 58-67 | 50-62 |

| Elongation na ezumike | ASTM D638 | 4-8% | 4-6% |

| Ike mmetụta, ọpụrụiche lzod, J/m | ASTM D256 | 18-30 | 16-23 |

| Okpomọkụ ngbanwe, ℃ | ASTM D 648 @66PSI | 81 | 98 |

| Ntugharị iko, Tg, ℃ | DMA, elu | 100 | 111 |

| Ọnụọgụ nke mgbasawanye thermal, E6/℃ | TMA (T | 79 | 86 |

| Nrụpụta ọkụ, W/m.℃ | 0.171 | ||

| Njupụta | 1.24 | ||

| Ntinye mmiri | ASTM D 570-98 | 0.49% | 0.46% |

Njirimara arụrụ arụ nke ihe emechara ka emechara

| Nhazi | UZỌ anwale

|

| URU |

|

|

| Ngwọta UV nke nkeji 90 | 90 nkeji UV +2 awa @ 160℃thermalmgbe ọgwụgwọ gasịrị |

| Hardness, Shore D | ASTM D2240 | 87 | 91 |

| Mgbanwe mgbanwe, Mpa | ASTM D790 | 2678-3186 | 3502-3631 |

| Ike mgbanwe, Mpa | ASTM D790 | 60-80 | 90-101 |

| modul tensile, MPa | ASTM D638 | 2840-3113 | 3484-3771 |

| Ike tensile, MPa | ASTM D638 | 58-67 | 50-62 |

| Elongation na ezumike | ASTM D638 | 4-8% | 4-6% |

| Ike mmetụta, ọpụrụiche lzod, J/m

| ASTM D256

| 18-30

| 16-23 |

| Okpomọkụ ngbanwe,℃

| ASTM D 648 @66PSI

| 81 | 98

|

| Ntugharị iko,Tg ,℃ | DMA,E”elu

| 100 | 111

|

| Ọnụọgụ nke mgbasawanye thermal, E6/℃ | TMA(T)

| 79

| 86

|

| Nrụpụta ọkụ, W/m.℃ |

| 0.171 |

|

| Njupụta |

| 1.24 |

|

| Ntinye mmiri | ASTM D 570-98 | 0.49% | 0.46% |