Resin-SZUV-S9006-e phahameng ho tiea

Kenyelletso ea Lisebelisoa tsa Khatiso tsa 3D

Litšobotsi

SZUV-S9006

TLHALOSO EA SEHLAHISOA

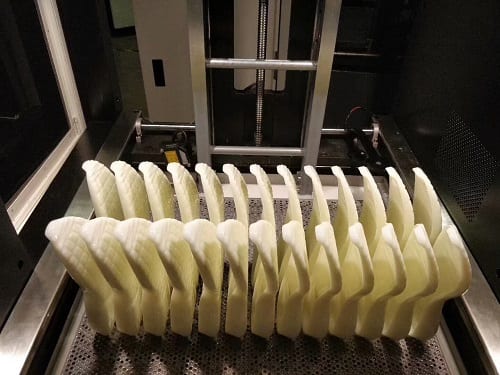

SZUV-S9006 ke ABS e kang SL resin e nang leboima bo phahamengLikaroloana. E etselitsoe bahatisi ba SLA ba mmuso. SZUV-S9006 e ka sebelisoa ka mekhoa e metle, mehlala ea mehopolo, likarolo tsa kopano le li-prototype tse sebetsang lebaleng la indasteri ea likoloi, tsa bongaka le tsa bareki. Moaho oa likarolo tse tšoarellang ka SZUV-S9006 o feta 6.5months.

MOEKETSILIKAROLOANA

-Liquid resin's viscosity e mahareng, ho bopeha habonolo, ho bonolo ho hloekisa likarolo le mechini

- Matla a ntlafalitsoeng a bolokoa, ho boloka litekanyo tse ntlafalitsoeng tsa likarolo tse maemong a mongobo

-e hloka ho qeta karolo e nyane

-Bophelo ba nako e telele mochining

-Tlasekhutsufatso e tlase

MOEKETSIMOLEMO

- E hloka nako e fokolang ea ho qeta, ho bonolo ho e phekola

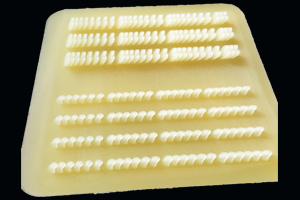

-Bulid likarolo tse nepahetseng le tse thata tse phahameng tse nang le botsitso bo ntlafalitsoeng ba sebopeho

- Litaolo tsa boleng bo holimo bakeng sa likarolo tsa vacuum casting

- Ho honyela ho tlase mme ho hanyetsana hantle le mosehla

-Mmala o mosweu o kgabane

- Lintho tse ikhethang tsa SLA tse ka sebelisoang

Tlhokomeliso: mocheso oa szuv-s9006 ha oa lokela ho ba o phahameng haholo. Ka kopo e sebelise ka tlase ho 25 ℃. Mongobo o lekanyelitsoeng bakeng sa tšebeliso le polokelo o tlameha ho ba ka tlase ho 38RH%.

LIEKETSENG TSA KA

Thuto

Mefuta ea matsoho

Likarolo tsa Auto

Moqapi oa Liphutheloana

Moqapi oa Litšoantšo

Bongaka

Thepa ea Sebele (Mokelikeli)

| Ponahalo | Bosoeu |

| Botenya | 1.11-~1.15g/cm3@25 ℃ |

| Viscosity | 230 ~ 290cps @ 26 ℃ |

| Dp | 0.13 ~ 0.145 limilimithara |

| Ec | 9.5 ~ 10.5 mJ/cm2 |

| Botenya ba lera la mohaho | 0.05 ~ 0.12 limilimithara |

Mechanical Properties (Kamora ho Phekoa)

| LEKOLA | TEKO MOKHOA | VALUE |

| Pheko ea kamora metsotso e 90 ea UV | ||

| Hardness, Shore D | ASTM D2240 | 75-85 |

| Flexural modulus, Mpa | ASTM D790 | 2,592-2,675 |

| Flexural matla, Mpa | ASTM D790 | 63-70 |

| Tensile modulus, MPa | ASTM D638 | 2,489-2,595 |

| Matla a tsitsitseng, MPa | ASTM D638 | 36-53 |

| Elongation nakong ya khefu | ASTM D638 | 15-25% |

| Karolelano ea Poisson | ASTM D638 | 0.4-0.44 |

| Matla a ts'ebetso a notletsoe Izod, J/m | ASTM D256 | 45-70 |

| Mocheso oa ho kheloha mocheso, ℃ | ASTM D 648 @66PSI | 38-50 |

| Phetoho ea khalase,Tg | DMA, E”tlhōrō | 40-54 |

| Coefficient ea katoloso ea mocheso | TMA(T | 90~102*E-6 |

| Boima ba 'mele, g/cm3 | 1.12-1.18 | |

| Dielectric Constant60 Hz | ASTM D 150-98 | 4.2-5.0 |

| Dielectric Constant 1 kHz | ASTM D 150-98 | 3.3-4.2 |

| Dielectric Constant1 MHz | ASTM D 150-98 | 3.2-4.0 |

| Matla a Dielectric V/mm | ASTM D 1549-97a | 12.8-16.1 |