Resin-SZUV-S9006-high tenacity

Gabatarwar Kayan Buga na 3D

Halaye

Saukewa: SZUV-S9006

BAYANIN KYAUTATA

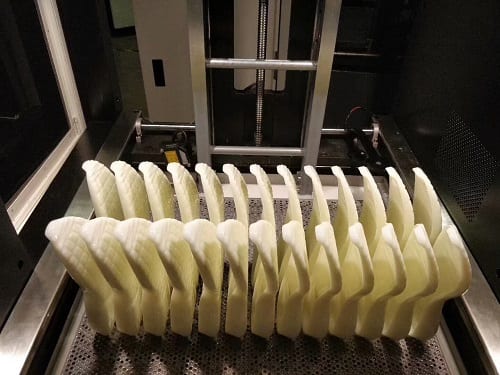

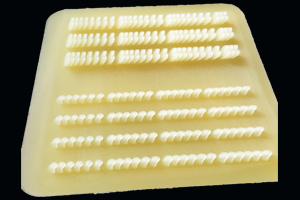

SZUV-S9006 shine ABS kamar resin SL wanda ke dahigh-taurifasali. An ƙera shi don firintocin SLA masu ƙarfi. Ana iya amfani da SZUV-S9006 a cikin ƙirar ƙira, ƙirar ra'ayi, sassan taro da samfuran aiki a fagen masana'antar kera motoci, likitanci da masana'antar lantarki. Ginin dorewar sassan da SZUV-S9006 ya wuce watanni 6.5.

MALALASIFFOFI

-Matsakaicin danko mai ruwa, mai sauƙin sakewa, mai sauƙin tsaftace sassa da injuna

-Ingantacciyar ƙarfin riƙewa, ingantaccen girman riƙe sassa a cikin yanayin ɗanɗano

-buƙatar ƙarancin ƙarewar sashi

- Tsawon rayuwa a cikin injin

-Ƙanananraguwar ƙasa

MALALAAMFANIN

- Bukatar ƙarancin lokacin ƙarewa, sauƙin warkewa

-Bulid daidai kuma manyan sassa masu tauri tare da ingantacciyar kwanciyar hankali

-Maɗaukaki masu inganci don ɓangarori na simintin ƙarfe

-Ƙananan raguwa da kyakkyawan juriya ga rawaya

-Mai girma farin launi

-Fitaccen machinable kayan SLA

Lura: zafin jiki na szuv-s9006 bai kamata ya yi girma ba. Da fatan za a yi amfani da shi ƙasa da 25 ℃. Dangin dangi don amfani da ajiya dole ne ya kasance ƙasa da 38RH%.

WASU DAGA CIKIN AYYUKA NA

Ilimi

Hannun Molds

Sassan Motoci

Marufi Design

Zane-zane

Likita

Abubuwan Jiki (Liquid)

| Bayyanar | Fari |

| Yawan yawa | 1.11-~ 1.15g/cm3@ 25 ℃ |

| Dankowar jiki | 230 ~ 290cps @ 26 ℃ |

| Dp | 0.13 ~ 0.145 mm |

| Ec | 9.5 ~ 10.5 mJ/cm2 |

| Gine-gine kauri | 0.05 ~ 0.12mm |

Kayayyakin Injini (Bayan-Cured)

| AUNA | HANYAR GWADA | DARAJA |

| 90-minti UV bayan magani | ||

| Hardness, Shore D | Saukewa: ASTM D2240 | 75-85 |

| Modules mai sassauci, Mpa | Saukewa: ASTM D790 | 2,592-2,675 |

| Ƙarfin sassauƙa, Mpa | Saukewa: ASTM D790 | 63-70 |

| Modules tensile, MPa | Saukewa: ASTM D638 | 2,489-2,595 |

| Ƙarfin ɗaure, MPa | Saukewa: ASTM D638 | 36-53 |

| Tsawaitawa a lokacin hutu | Saukewa: ASTM D638 | 15-25% |

| Rabon Poisson | Saukewa: ASTM D638 | 0.4-0.44 |

| Ƙarfin tasirin Izod, J/m | Bayani na ASTM D256 | 45-70 |

| Zafin karkatar da zafi, ℃ | ASTM D 648 @ 66PSI | 38-50 |

| Canjin Gilashi, Tg | DMA, E” kololuwa | 40-54 |

| Coefficient na thermal kashe kudi | TMA (T | 90-102*E-6 |

| Yawan yawa, g/cm3 | 1.12-1.18 | |

| Dielectric Constant 60 Hz | Saukewa: ASTM D150-98 | 4.2-5.0 |

| Dielectric Constant 1 kHz | Saukewa: ASTM D150-98 | 3.3-4.2 |

| Dielectric Constant 1 MHz | Saukewa: ASTM D150-98 | 3.2-4.0 |

| Ƙarfin DielectricV/mm | Saukewa: ASTM D1549-97A | 12.8-16.1 |