Bottom price Printer 3d Model - Hot sale Creality 3d Ld-001 3d Printer 450nm Resin Uv-led Precision 2k Lcd Screen – Digital Manufacturing

Bottom price Printer 3d Model - Hot sale Creality 3d Ld-001 3d Printer 450nm Resin Uv-led Precision 2k Lcd Screen – Digital Manufacturing Detail:

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our business for your long-term to develop with each other with prospects for mutual reciprocity and mutual profit for Hot sale Creality 3d Ld-001 3d Printer 450nm Resin Uv-led Precision 2k Lcd Screen, Welcome you to definitely be part of us alongside one another to make your organization easier. We have been normally your greatest partner when you want to have your own small business.

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our business for your long-term to develop with each other with prospects for mutual reciprocity and mutual profit for 3dprinter, Lcd Screen, Precision, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.

RP technology introduction

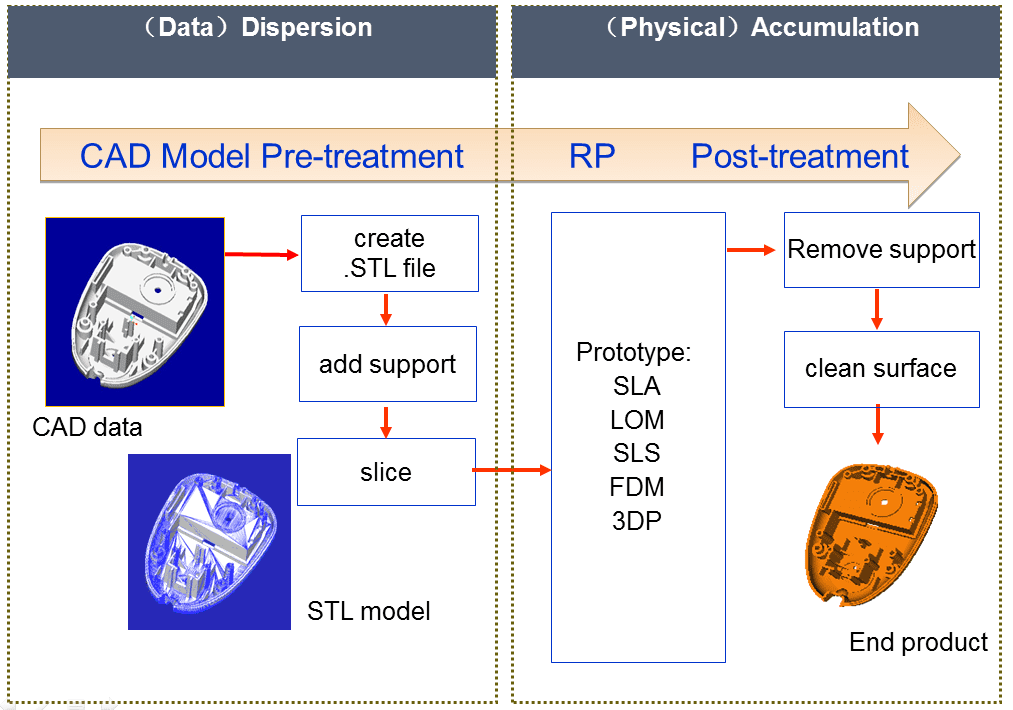

Rapid Prototyping (RP) is a new manufacturing technology that was first introduced from the United States in the late 1980s. It integrates modern scientific and technological achievements such as CAD technology, numerical control technology, laser technology and material technology, and is an important part of advanced manufacturing technology. Unlike traditional cutting methods, rapid prototyping uses a forming mechanism in which layered materials are superimposed to machine a three-dimensional part prototype. Firstly, the layering software slices the CAD geometry of the part according to a certain layer thickness, and obtains a series of contour information. The forming head of the rapid prototyping machine is controlled by the control system according to the two-dimensional contour information. Solidified or cut to form thin layers of various sections and automatically superimposed into three-dimensional entities

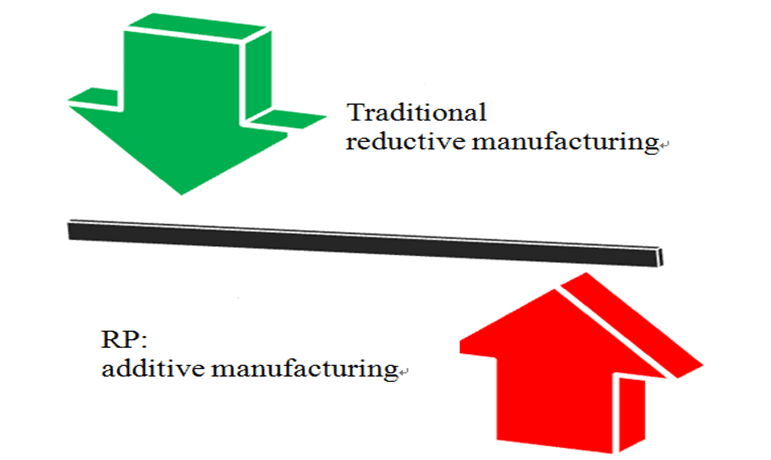

Additive manufacturing

Unlike traditional reductive manufacturing, RP uses a layer-by-layer material accumulation method to process solid models, so it is also called Additive Manufacturing, (AM) or Layered Manufacturing Technology, (LMT).

Characteristics of RP technique

Highly flexible, it can produce any 3D solid models of any complex structure, and the production cost is almost independent of the complexity of the product.

CAD model direct driving, the molding process is completely digital, no special fixtures or tools are required, and design and manufacturing (CAD/CAM) is highly integrated.

High accuracy,±0.1%

Highly reductive, capable of making very fine details, thin walls

Mold surface quality is excellent

Fast speed

Highly automated: the process is fully automated, the process requires no human intervention, and the equipment can be unattended

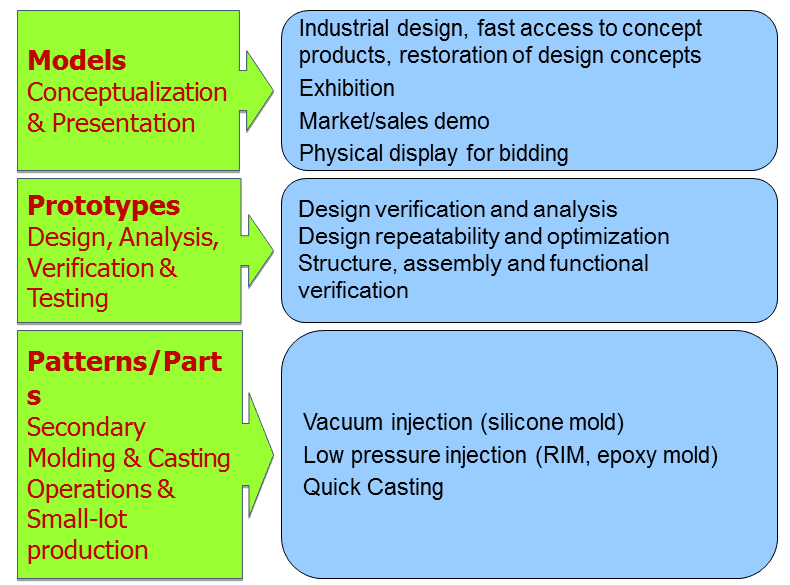

Applications of RP technology

RP technology is widely used in the areas:

Models (Conceptualization & Presentation):

Industrial design, fast access to concept products, restoration of design concepts, Exhibition,etc.

Prototypes (Design, Analysis, Verification & Testing):

Design verification and analysis, Design repeatability and optimization etc.

Patterns/Parts (Secondary Molding & Casting Operations & Small-lot production):

Vacuum injection (silicone mold),Low pressure injection (RIM, epoxy mold) etc.

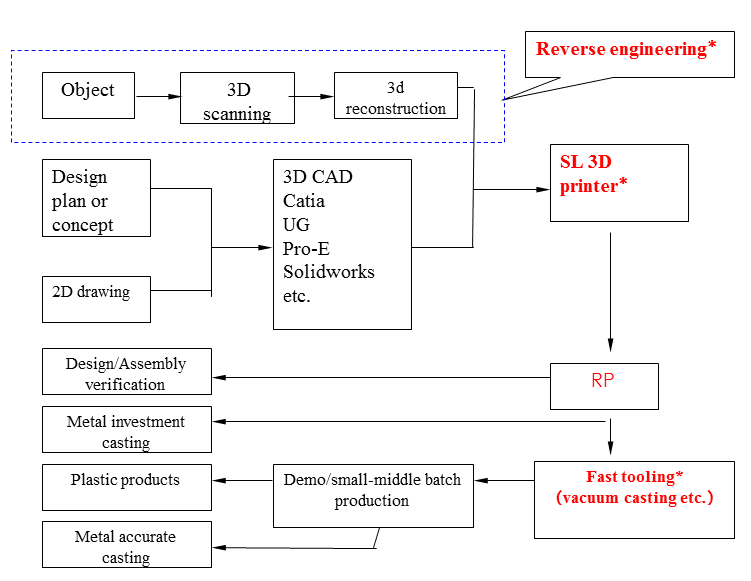

Application process of RP

The application process can start either from an object,2D drawings or just an idea. If only the object is available, the first step is to scan the object to get an CAD data, go to revese engineeing process or just amendment or modification and then begin the RP process.

If 2D drawings or idea exists, it is necessary to go to 3D modeling procedure using the special software, and then go to the 3D prining process.

After RP process, you can get the solid model for functional test, assembly test or go to other procedures for casting according to actual needs of clients.

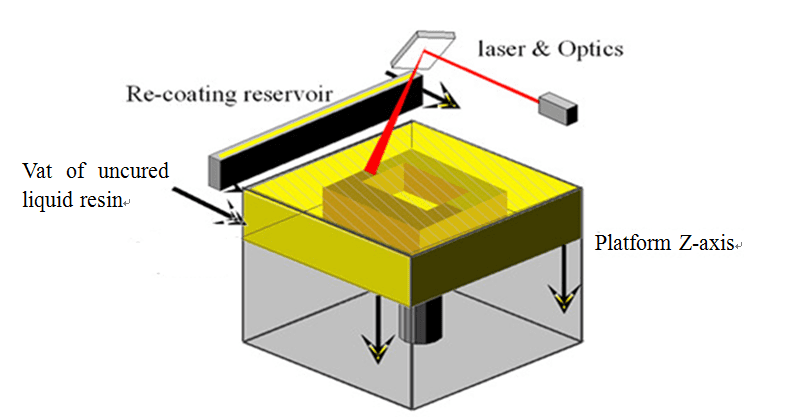

Introduction of SL technology

The domestic name is stereolithography, also known as laser curing rapid prototyping. The principle is: the laser is focused onto the surface of the liquid photosensitive resin and scanned according to the cross-sectional shape of the part, so that it is selectively cured, from point to line to the surface, to complete the curing of one layer, and then the lifting platform is lowered by one layer thickness and recoated with a new layer a resin and cured by laser until the whole solid model is formed.

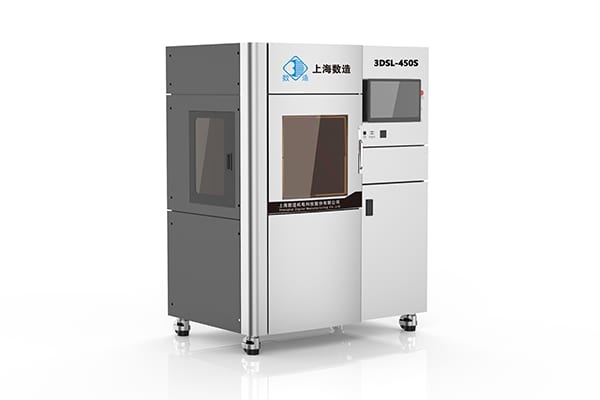

Advantage of 2nd Generation of SL 3D Printers of SHDM

High efficiency, and maximum speed can reach 400g/h and the productivity in 24 hours can reach10kg.

Large build volumes, available size are 360*360*300(mm),450*450*330(mm),600*600*400(mm),800*800*550(mm), and other customized build volumes.

Material performance is cheap and highly improved in the aspects of strength, tenacity and high-temperature resistance, suitable for engineering applications.

Obviously improved in the size precision and stability.

Multiple parts can be treated at the same time in the control software and there is perfect parts self-composing function.

Suitable for small batch production.

Unique nest technology of resin tanks with different volume, 1 kg resin can be printed, which is especially suitable for the research and development.

Replaceable resin tank, different resin can be changed easily.

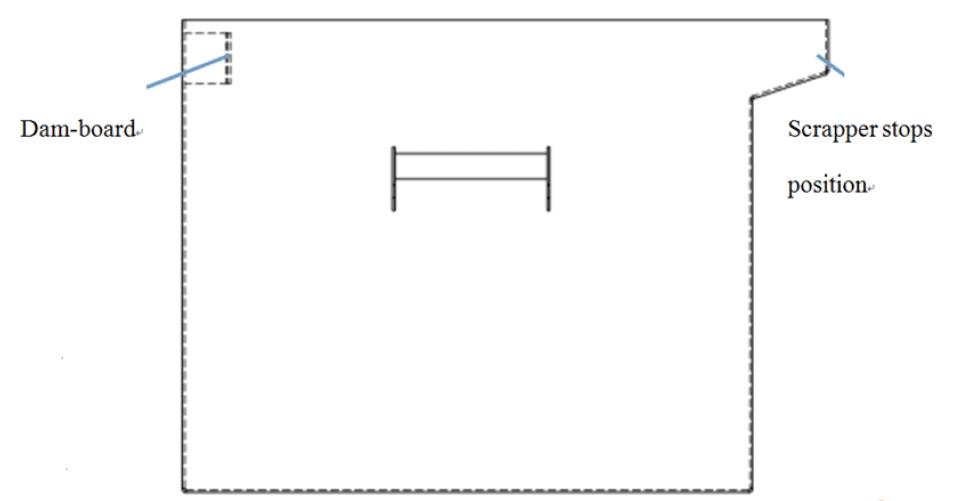

Replaceable resin tank

Only pull out and push in, you can print a different resin.

Resin tank of 3DSL series is changeable (Except 3DSL-800). For the 3DSL-360 printer, the resin tank is with the drawer mode, when replacing the resin tank, it is necessary to lower the resin tank to the bottom and lift two lock catches, and pull the resin tank out. Pour new resin after cleaning the resin tank well, and then lift the lock catches and push the resin tank into the printer and lock well.

3DSL-450 and 3DSL 600 is with the same resin tank system. There are 4 trundles at beneath of the resin tank to facilitate pulling out and pushing in.

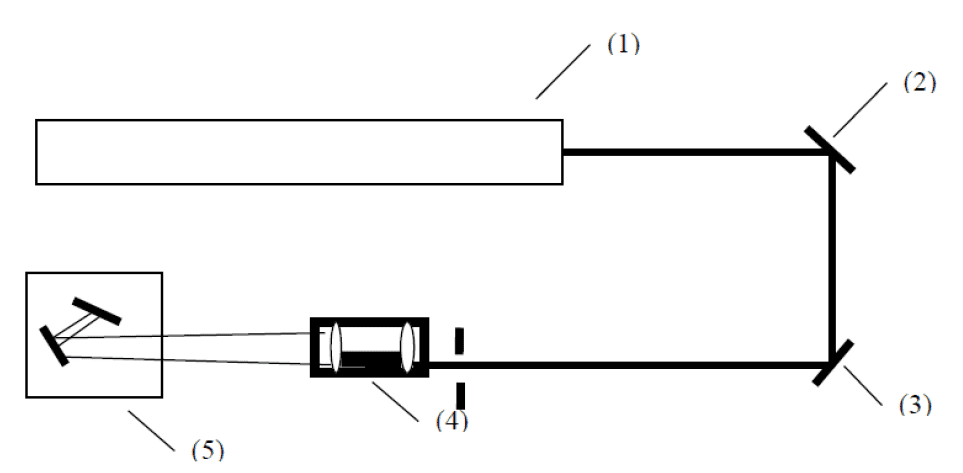

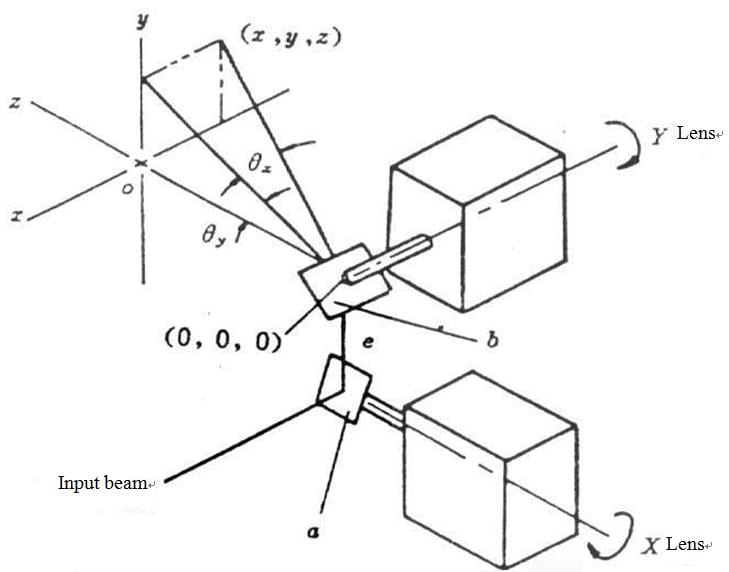

Optical system-Powerful solid laser

3DSL series SL 3D printers adopts the high powerful solid laser device of 3W and continuous output wave length is 355nm. Output power is 200mw-350mw, air cooling and water cooling are optional.

(1). Laser Device

(2). Reflector 1

(3). Reflector 2

(4). Beam Expander

(5). Galvanometer

High efficiency Galvanometer

Max scanning speed: 10000mm/s

Galvanometer is a special swing motor, its basic theory is same as the current meter, when a certain current passes through the coil, the rotor will diverge a certain angle, and the deflection angle is proportional to the current. So the galvanometer is also called galvanometer scanner. Two vertically installed galvanometer form two scanning directions of X and Y.

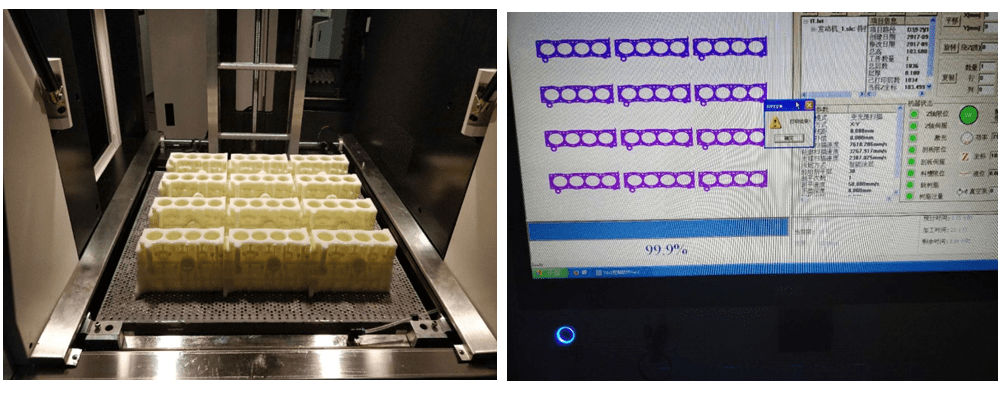

Productivity test-car engine block

Testing part is a car engine block, Part size: 165mm×123mm×98.6mm

Part volume: 416cm³, Print 12 pieces at the same time

Total weight is about 6500g, Thickness: 0.1mm, Strickle speed: 50mm/s,

It takes 23 hours to finish, average 282g/h

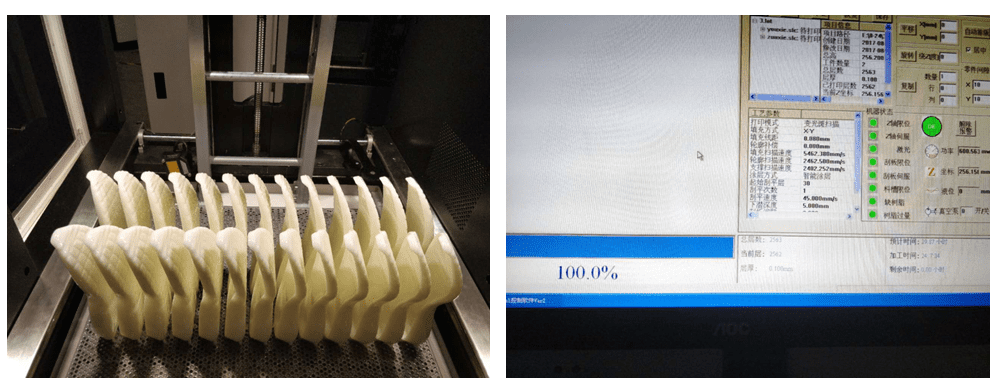

Productivity test- shoe soles

SL 3D printer: 3DSL-600Hi

Print 26 shoe soles at the same time.

It takes 24 hours to finish

Average 55 min for one shoe sole

Download brochure

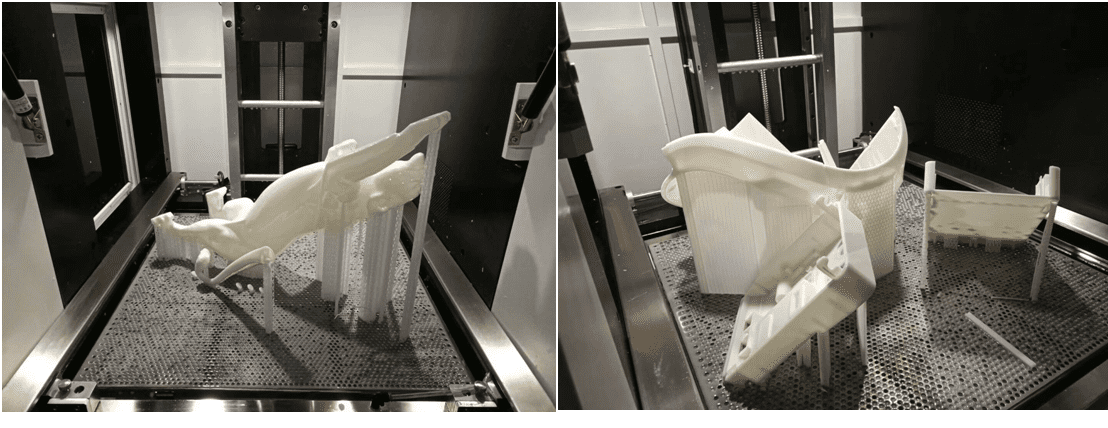

Application areas

Education

Rapid prototypes

Automobile

Casting

Art Design

Medical

Product detail pictures:

Related Product Guide:

Air Force Research Laboratory Testing 3D Printed Parts for Motors | 3DPrint.com | Best 3d Scanner 2019

Ahead of Super Bowl 2019, 3D printing promises safer football helmets | Most Expensive 3d Printer

We thinks what customers think, the urgency of urgency to act in the interests of a customer position of principle, allowing for better quality, lower processing costs, prices are more reasonable, won the new and old customers the support and affirmation for Bottom price Printer 3d Model - Hot sale Creality 3d Ld-001 3d Printer 450nm Resin Uv-led Precision 2k Lcd Screen – Digital Manufacturing , The product will supply to all over the world, such as: Malaysia, United Arab emirates, Porto, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!